Content Type:

Installation

Project Type:

Building

System Name:

Siding, T&G Planks

Installation:

Exterior

In the dynamic world of construction, adapting to new techniques and materials is essential. As project requirements evolve, so does the demand for innovative solutions in cladding systems. At Longboard, we’ve developed a range of cladding trims ensure functionality without compromising aesthetics.

This guide provides an overview of the various conditions you might encounter when installing cladding and the appropriate trims for each scenario, helping you achieve a seamless and visually appealing finish on your projects.

For detailed installation techniques and best practices, please refer to our installation guide. Proper installation ensures optimal performance and longevity.

Windows, Doors and Other Penetrations

Walls that are longer than 24’ (or 40’ with one butt joint)

Menu

Understanding the Basics

Corners

Windows, Doors and Other Penetrations

Starting a Run

Walls that are longer than 24’ (or 40’ with one butt joint)

Ending a Run

Between Floors

Understanding the Basics

Lengths

Most of our trim components come in standard 12’ lengths.

The only exceptions are our T&G Reveals, T&G Corner Planks, and Traditional Compression Joint, which all come in 24′ lengths.

Expansion and Contraction

All of our planks and trim components are made from aluminum, and therefore expand and contract at different values depending on temperature. To ensure successful installation, all planks must be installed to accommodate the approximate ¼” (6mm) movement over 24’ (7.3m), measured at a 54°F (30°C) temperature range.

For more information, please see the expansion and contraction tables located in our Tongue & Groove Plank Installation Guide.

Attachment

Attachment will ultimately depend on substrate, wind loads and local building jurisdiction. Below are our requirements under normal conditions. Always consult our installation guide for wind load span tables.

Planks must be secured with our quick-screen clips every 32” on-center.

All planks must be hard fastened once, typically at the center of the plank. The only exception to this rule is when using butt joints.

Butt joints must be hard fastened at the joint.

All trims must be hard fastened at 16″ on-center. Check our Installation Guide for specifics.

The back-to-back starter strip must be fastened on both sides of the trim with our quick-screen clips fastened at 16″ on-center.

Precision, Craftsman, and Traditional Styles

Precision, Craftsman, and Traditional refer to trim styles, representing the final aesthetic after installation.

An easy way to visualize these is by thinking of small (Precision), medium (Craftsman), and large (Traditional) trims. The choice depends entirely on the desired aesthetic and the job site’s requirements. Precision trims deliver a crisp, modern look, while Traditional trims provide greater flexibility, accommodating various installation conditions with ease and offering a more classic appearance. Craftsman trims strike a balance, blending the clean lines of Precision with the flexibility of Traditional trims.

Horizontal Applications

This guide assumes all preparation work is completed as outlined in our installation guide. This includes having the right power tools, fasteners, complete and accurate measurement of the wall, windows, and other penetrations. This guide is primarily to walk through the trim options you have at each wall condition.

Corners

Corners are the first step to setting up our cladding system. Depending on whether it is an outside or inside corner, we have a few different options available.

Outside Corner

Precision Outside Corner

For the most subtle corner trim, we have our Precision Outside Corner trim. This component does not leave a lot of room for error but in return has the most seamless and clean appearance. Planks must be mitered at a 45° angle and hard fastened onto the trim. Due to the hard fastening onto the trim, a component that allows for expansion (expansion trim, return, another corner transition, etc.) must be used within the next 6 ft. from the precision trim to allow space for the expansion and contraction of the plank.

Craftsman Outside Corner

Similar to the inside corner, the Craftsman Outside Corner is a one-piece extrusion that is a good middle ground between aesthetics and functionality. Similar to all our other trims, it is attached directly to the substrate, hard fastened at 16” on-center.

Traditional Corner Set

The same trim that is used on inside corners can also be used for outside corners. The only difference is the base used.

Inside Corner

Craftsman Inside Corner

The first option for an inside corner is our craftsman style trim. This is a one-piece extrusion, which will bolt on and attach to the substrate of the building. Craftsman style trims are a good middle ground for having easy-to-install trims while not being overly intrusive to the wall aesthetics.

Traditional Corner Set

The second option is a two-piece set, where the base will be installed first, and the cap will be installed after all planks have been installed. Traditional style trims offer a classic appearance while allowing greater flexibility in installation accuracy. The Traditional Corner Set can be used for inside and outside corners.

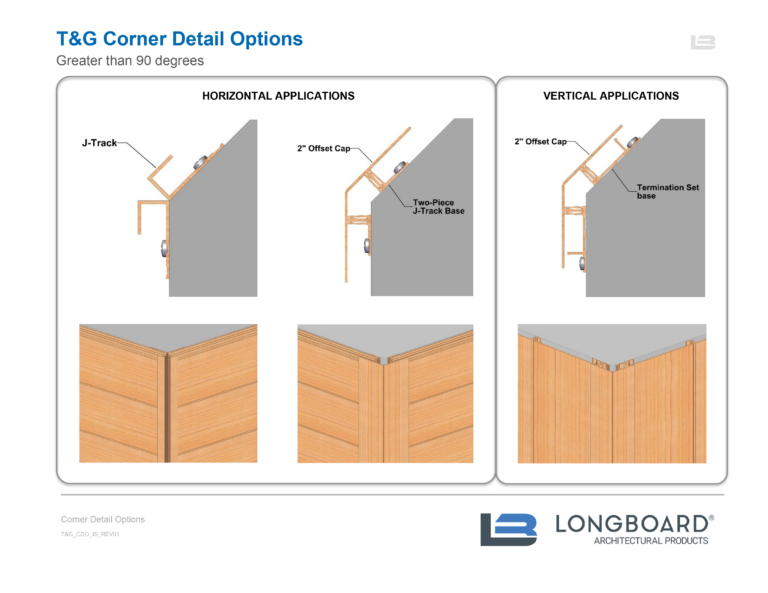

Corners that aren’t 90°

For corners that are not exactly 90°, there are two options:

The simplest approach is to use two single-piece J-tracks placed back-to-back. This method naturally creates a reveal and aligns with the standard process for installing trims and planks.

The second option is a more advanced technique that demands considerable precision to achieve a nearly seamless appearance. Start by installing a two-piece J-track on each side of the corner. Then, snap the 2″ Traditional Offset Reveal Cap onto each trim. With proper alignment of the bases, this results in a nearly continuous aesthetic.

Windows, Doors and Other Penetrations

Choosing a trim for an envelope penetration is fairly simple for horizontal applications. The majority of the time, you will be using one of our J-Track trims unless you are trimming the underside of a window or similar feature. In that case, you would use our Termination Set.

Sides & Header of Windows, Doors and Other Penetrations

As mentioned, for the sides and header of windows or similar features, you will be generally using our single or two-piece J-Track. Which you choose will depend on the aesthetics desired and project requirements. The measurements below refer to the length of the trim that will be visible after all components have been installed.

Styles for Single-Piece J-track:

- Precision J-Track – The smallest of our J-track trims, measuring ⅝” long.

- Craftsman J-Track – A slightly larger single-piece trim, measuring ⅞” long.

Styles for Two-Piece J-track:

- Precision J-Track – The smallest trim, measuring ⅝” long.

- Craftsman J-Track – A good middle ground trim, measuring ⅞” long.

- Traditional J-Track – The largest of our trims for a classic aesthetic, measuring 1-⅜” long.

Our two-piece J-track simplifies the installation of our planks. By installing just the base first, the plank can be placed directly against the wall rather than being slid in at an angle, as required with one-piece trims. The cap is then snapped on after the plank is fully installed.

Underside of a Window or Similar Penetration

For the underside of a window, electrical box, light fixture, or similar a Termination Set is needed. The Termination Set has specific support integrated into its design, specifically made for ending runs. It is also compatible with ripped planks, providing the support needed to prevent the plank from caving inwards. It comes in two pieces, a base extrusion, and a cap. Options are as follows:

- Precision Termination Set – The smallest trim, measuring ⅝” long.

- Craftsman Termination Set – A good middle ground trim, measuring ⅞” long.

- Traditional Termination Set – The largest of our trims for a classic aesthetic, measuring 1-⅜” long.

Starting a Run

After the corners and penetrations have been figured out, it is now time to trim the start of a run. There are two options, which mainly depend on the aesthetics desired.

Our first option is our Starter J-Track, which follows the aesthetics of the regular J-track, with an additional tongue to engage the bottom of the plank.

Our secondary option is our Starter Strip. This trim gives the impression of a trimless installation, for a clean and crisp aesthetic.

Both options must be fastened every 32” on-center, determined by wind load requirements. To ensure proper water drainage, a quick screen clip is also installed 32” on-center.

Walls that are longer than 24’ (or 40’ with one butt joint)

After the starter strip is installed, walls longer than 24 feet require either a “reveal” trim or a staggered butt joint. When using a butt joint, the maximum wall length increases to 40 feet before a reveal trim becomes necessary.

Our planks and components expand and contract by ¼ of an inch (6 mm) over a 24-foot (7.3 m) length within a temperature range of 54°F (30°C). To accommodate this movement, reveal trims are essential to provide adequate space for expansion and contraction. These trims, available in single-piece and two-piece options, are installed perpendicular to the planks in both horizontal and vertical applications.

Single-Piece Reveals

- Precision Flat Reveal: This one-piece trim is designed to maintain a sleek, unobtrusive aesthetic. The finished trim measures 17⁄36 of an inch wide. Precise installation is critical, as the trim allows ¼ inch of movement on either side of the plank for expansion and contraction.

- Precision T&G Flat Reveal: Similar to the Precision Flat Reveal, this trim is tailored for Tongue & Groove (T&G) planks. It conceals the trim for a seamless wall appearance.

- Precision T&G U-Reveal: This trim introduces a distinct separation between plank runs, creating a panelized aesthetic. It features a ¼-inch shadow line for subtle visual contrast.

- Craftsman T&G U-Reveal: An enhanced version of the Precision T&G U-Reveal, this trim offers a more pronounced shadow line, measuring 3⁄8 of an inch, for a bolder look.

Two-Piece Set Reveals

Set Reveals consist of a base piece and a cap, providing easier installation.

- Traditional Flat Reveal Set: The largest flat reveal in our lineup, ideal for significant coverage.

- Craftsman U-Reveal Set: Similar in appearance to the Craftsman T&G U-Reveal but without the specific Tongue & Groove design.

- Traditional U-Reveal Set: The largest option in the U-Reveal family, designed for dramatic separation between planks.

Butt Joints

Butt joints have a few benefits, such as minimizing waste of off-cut materials and the ability to extend a plank run up to 40’ before installing a reveal trim.

Important note: A single run can only have one butt joint, and they must be staggered vertically across the wall. Improper installation of butt joints can leave a large gap between planks, creating an undesired aesthetic.

For designers considering butt joints across their façade, a great add-on is our T&G Butt-joint Fastening Kit. This kit simplifies installations and reduces the chances of a butt-joint failure due to improper installation.

Ending a Run

To end a run, our two-piece Termination Sets are utilized. Our termination trim sets are meant to be installed parallel to the plank, generally at points where no other plank will be attached past the trim. This includes the underside of windows and the top of the wall for horizontal cladding. The options are:

Precision Termination Set – The smallest of the termination sets, measuring ⅝” long.

Craftsman Termination Set – The medium-sized set, measuring ⅞” long.

Traditional Termination Set – The largest set, measuring 1-⅜” long.

Similar to previous components, the style of each set simply determines the finished aesthetic. Precision is the smallest trim for a clean and cohesive look, while Traditional is the largest trim for the most flexibility and ease of installation.

Between Floors

For projects that do not require through wall flashing by design or building jurisdiction, we offer our compression joint.

The compression joint is perfect for projects that experience compression at each elevation. A great example is wood frame construction, in which natural compression occurs as the wood dries out and settles. In such scenarios, we recommend a compression joint at every elevation.