Content Type:

Installation, Performance & Testing

Project Type:

-

System Name:

Hitch™

Installation:

Exterior

On This Page ▶

Rainscreen systems are exterior cladding solutions designed to enhance moisture management, improve thermal efficiency, and extend the durability of building envelopes. Developed in Europe and Canada in the mid-20th century, rainscreens were created to address persistent moisture-related issues that traditional wall assemblies struggled to manage, particularly in rainy and humid climates. The rainscreen concept is based on creating an air gap between the exterior cladding and the building’s structural wall, allowing moisture that penetrates the cladding to drain and dry. This separation prevents moisture from becoming trapped, reducing the risks of mold growth, structural decay, and damage to insulation.

The benefits of rainscreen systems have driven their widespread adoption, especially in North America, where building codes increasingly emphasize energy efficiency and resilience. Beyond moisture control, rainscreens play a significant role in moderating thermal loads. By stabilizing temperatures within the wall assembly, they help maintain the effectiveness of insulation, support energy efficiency, and contribute to occupant comfort. These combined benefits of moisture management, thermal performance, and long-term durability make rainscreen systems a cornerstone of modern, high-performance building

What Are Cladding Attachment Systems?

Cladding attachment systems are structural components essential to the functionality of rainscreen assemblies. These systems secure the exterior cladding to the building structure while maintaining a critical air gap between the cladding and the wall. This air gap enables the passive drainage and ventilation necessary to prevent moisture buildup and to keep the wall assembly dry.

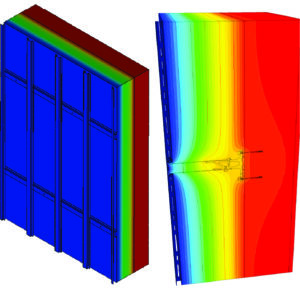

In addition to supporting moisture control, cladding attachment systems directly impact the thermal performance of the wall assembly. The materials and design of these systems determine the extent of thermal bridging, which occurs when conductive materials bypass insulation and allow heat to flow through the wall. High levels of thermal bridging reduce the effective R-value of the wall and compromise energy efficiency. By minimizing thermal bridges, cladding attachments allow insulation to perform closer to its rated R-value, supporting the rainscreen’s role in a well-insulated, energy-efficient building envelope.

Ultimately, cladding attachment systems ensure both the physical stability and environmental resilience of the rainscreen assembly, making them integral to the overall durability and integrity of the building envelope.

Types of Cladding Attachment Systems

There are several categories of cladding attachment systems, each offering distinct advantages and trade-offs based on structural requirements, thermal performance, and ease of installation. Key categories include continuous framing systems, clip and rail systems, long screws through insulation, and masonry ties.

Continuous Framing Systems

Continuous framing systems, such as Z-girts, provide robust support for cladding but are thermally inefficient due to the continuous metal paths they create through the insulation. Continuous framing can be installed vertically, horizontally, or in a crossing pattern. However, these systems result in significant thermal bridging, reducing insulation effectiveness to about 20-60%, depending on configuration and spacing. Despite their structural strength, continuous framing systems are less commonly used in energy-efficient designs due to their impact on thermal performance.

Clip and Rail Systems

Clip and rail systems provide a more thermally efficient solution by using intermittent clips that minimize conductive materials penetrating the insulation layer. These systems, including aluminum T-clips, adjustable aluminum clips, galvanized steel clips, and fiberglass clips, vary in thermal performance based on material and spacing. Fiberglass clips are one of the most thermal efficient systems, retaining up to 95% of insulation effectiveness. Clip and rail systems are versatile and can accommodate a range of cladding materials, making them ideal for both commercial and residential applications where energy efficiency is a priority.

Long Screws Through Insulation

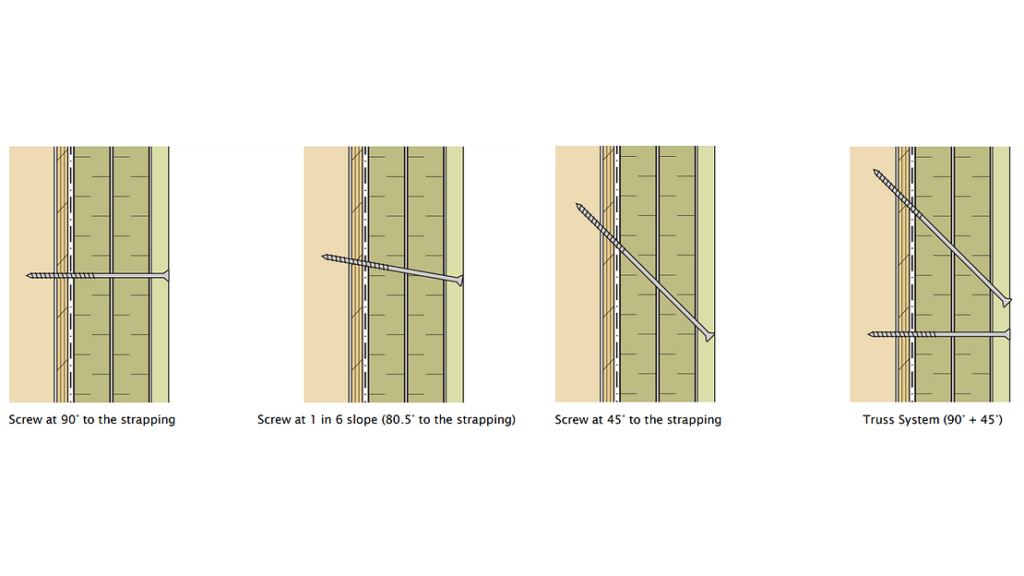

The long screw attachment method involves fastening cladding through rigid insulation directly to the structural wall. While long screws reduce the number of metal components penetrating the insulation, they still create thermal bridges that impact overall thermal performance, with typical insulation effectiveness ranging from 75–95% depending on material and screw spacing. This method is often used in lower-rise construction where structural demands are moderate.

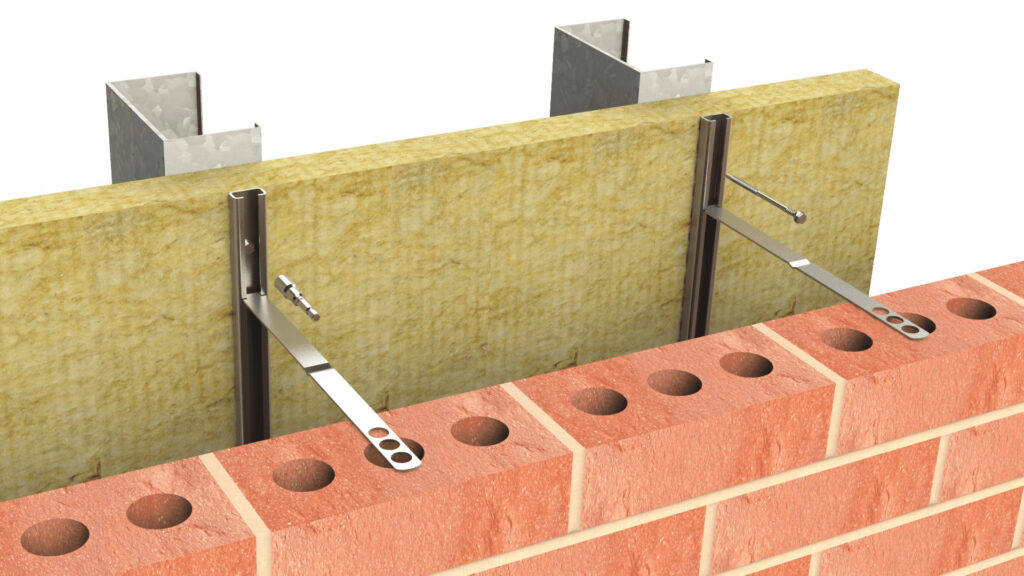

Masonry Ties

Masonry ties are used in rainscreen assemblies with masonry veneers, providing lateral support and stability for materials like brick and stone. While structurally sound, masonry ties can introduce thermal bridging based on their material and spacing, with stainless steel ties offering better thermal performance. Thermal efficiency in systems using masonry ties ranges from 40–90%, depending on the density and type of tie material used.

Understanding High-Performance Cladding Attachment Systems

High-performance cladding attachment systems are engineered to meet the demands of modern, energy-efficient construction by addressing the thermal limitations of traditional methods. These advanced systems incorporate low-conductivity materials and designs that limit thermal bridging, allowing the wall to retain more of the insulation’s rated performance. High-performance systems are not only intended to meet the structural and moisture management needs of rainscreens but also to enhance the wall assembly’s energy efficiency.

What sets these systems apart is their optimized thermal design, which strategically minimizes conductive material pathways through insulation. This reduction in thermal bridging enables high-performance systems to meet increasingly stringent energy codes and building standards that prioritize sustainability and occupant comfort. Additionally, high-performance systems support continuous insulation, ensuring that there are minimal interruptions in the insulating layer, which is crucial for preventing energy losses in the building envelope

Characteristics of High-Performance Systems

High-performance cladding attachment systems possess several defining attributes that contribute to their superior performance. First, these systems use low-conductivity materials, which limit heat transfer through the wall and reduce the impact of thermal bridging. Materials like fiberglass and stainless steel have lower thermal conductivity than galvanized steel or aluminum, making them ideal for applications that prioritize energy efficiency. By minimizing the conductive pathways through the insulation layer, these materials allow high-performance systems to achieve significantly higher thermal efficiency compared to traditional methods.

Another important characteristic is the strategic placement of attachment points to support continuous insulation. High-performance systems are designed to minimize the frequency of attachments penetrating the insulation, allowing for a more seamless insulating layer. This continuity is essential for maintaining the wall’s effective R-value, as frequent interruptions in the insulation layer can compromise energy efficiency. By preserving a continuous layer of insulation, high-performance systems help meet strict energy codes and provide consistent thermal protection across the wall assembly.

In addition to thermal efficiency, high-performance cladding systems provide effective moisture management. The air gap they maintain behind the cladding allows for passive drainage and drying, ensuring that any moisture penetrating the outer layer can evaporate or drain away before it reaches the structural wall. This moisture management capability reduces the risk of mold growth, material decay, and other water-related damage, contributing to the longevity and resilience of the building envelope.

High-performance systems also accommodate various cladding types, including heavier options like stone and masonry. By using high-strength, low-conductivity materials, these systems are capable of supporting significant dead loads without compromising thermal performance, making them versatile for diverse facade designs and construction types. Constructability is another notable advantage of high-performance systems; their simplified designs often require fewer components and straightforward attachment methods, which can reduce labor costs and improve installation accuracy. This enhanced constructability ensures that the rainscreen assembly achieves its intended performance goals while supporting a more efficient construction process.

Performance Validation and Quality Assurance

For designers, ensuring that a high-performance cladding attachment system will meet the specific needs of a project involves a series of critical questions and considerations. Understanding the system’s impact on thermal efficiency, moisture management, and overall durability is crucial. Here are the main factors designers should address with manufacturers to ensure the chosen system meets performance expectations:

Requesting Thermal Performance Data

One of the most important aspects of system selection is understanding how well it minimizes thermal bridging. Designers should ask for detailed thermal modeling data, including U-value calculations for the entire wall assembly, as well as chi (χ) values that indicate point heat transfer through each attachment. Requesting results from standard tests, such as ASTM C1363, which measures thermal transmittance, will provide an accurate basis for comparing systems across different configurations and materials.

Confirming Third-Party Certifications

Third-party certifications provide objective assurance of a system’s performance. Designers should check for certifications from bodies like the Passive House Institute (PHI) or Passive House Institute U.S. (PHIUS), which set rigorous limits on thermal bridging. Verifying compliance with standards like ASTM or NFRC certifications for wall assemblies ensures the system meets recognized industry benchmarks. Additionally, certifications from green building programs such as LEED or BREEAM indicate that the system contributes to sustainable building goals.

Ensuring Structural Capacity and Compatibility with Cladding Loads

High-performance systems must support various cladding materials and weights. Designers should request structural performance data, especially for heavier claddings like stone or masonry, and inquire about spacing and attachment configurations to confirm compatibility with wind and seismic loads. Knowing the system’s capacity for dead and live loads, along with the specified spacing recommendations, ensures that the chosen attachment system will meet the project’s structural requirements without compromising thermal or moisture performance.

Requesting Information on Constructability and Installation Guidance

To avoid unexpected installation challenges, designers should ask about the constructability of the system. Inquiring about installation guides, detailing support, and training resources can help ensure that the system is installed accurately, maximizing its thermal and moisture management potential. Designers should also confirm the availability of technical support from the manufacturer, as well as documentation for any adjustments needed to maintain thermal efficiency and proper spacing during installation.

Future Outlook and Industry Trends

As building codes continue to evolve and energy efficiency requirements become more stringent, high-performance cladding attachment systems will play an increasingly vital role in sustainable construction. The industry is trending toward innovative materials and designs that further reduce thermal bridging while maintaining structural integrity. Emerging technologies in composite materials and advanced manufacturing processes are enabling the development of even more efficient attachment solutions.

As climate change drives more extreme weather conditions, these systems will become even more critical in creating resilient building envelopes that can adapt to varying environmental demands.

The success of high-performance cladding attachment systems ultimately depends on the careful balance of thermal efficiency, moisture management, structural capacity, and practical constructability. By understanding and implementing these systems effectively, designers and builders can create building envelopes that not only meet current performance standards but are also prepared for the challenges of tomorrow’s construction industry.

About Longboard Architectural Products

For nearly two decades, Longboard has been committed to creating innovative, sustainable, and inspiring products for the design and construction community. One of our key innovations is the HITCH™ Cladding Attachment System. Drawing from our expertise in the cladding space, we set out to elevate the standards of cladding attachment systems. After multiple iterations of development, we created a product that raises the performance expectations of cladding attachment systems.

Learn more about HITCH™ and its designer, Aaron Fraser, in the podcast below.