Replacing Standard Façade Anchor Systems with High-Performance Façade Anchor Systems: The Hidden Key to Building Envelope Efficiency

Content Type:

Case Study

Project Type:

Corporate & Commerical

System Name:

-

Installation:

Exterior

In the pursuit of high-performance buildings, energy efficiency is no longer achieved through insulation thickness alone. It depends on the seamless interaction between every layer and component that shapes the building envelope. Among these, one of the smallest and least visible details can have one of the biggest impacts: the façade anchoring system.

Building Efficiency Starts at the Anchor Point

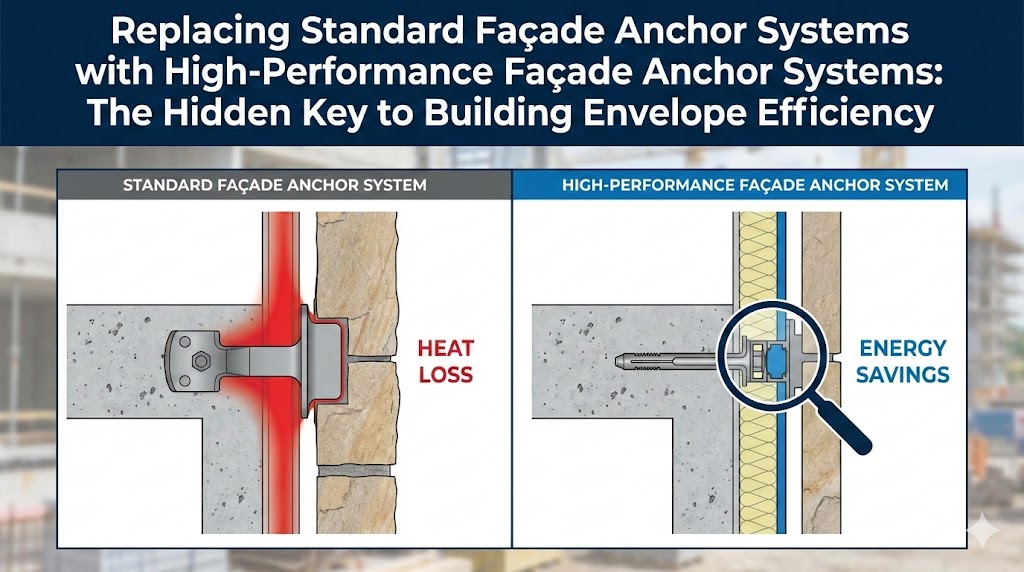

While architects and engineers dedicate significant attention to insulation types, glazing performance, and membrane continuity, the structural connection that ties the façade to the wall is often treated as a secondary detail. Yet that single detail can make or break the envelope’s performance. Traditional anchoring systems, with their dense grid of metal clips and brackets, create hundreds of penetrations through the insulation, each one a miniature thermal bridge. The result is a measurable loss of energy efficiency, comfort, and durability. For teams targeting Net-Zero or Passive House standards, those losses are no longer acceptable.

Thermal bridging is the silent enemy. Every balcony, parapet, window interface, and façade anchor provides a pathway for heat to escape. Even when the wall assembly is designed to achieve R-25 or better, conventional anchors can slash its effective value by half or more. In one typical simulation (images below), a wall initially rated at R-22.7 dropped to just R-13 once traditional anchors were included; a 70% loss in performance, with as many as 52 anchors in corner zones. Each of those penetrations also increases the risk of air leakage, condensation, and long-term maintenance issues.

The industry’s response has been a shift toward continuous exterior insulation, wrapping the building in a protective shell that minimizes heat loss. But the performance of this approach depends on how the façade is attached. Every bracket, clip, or girt must balance structural strength, constructability, and thermal isolation. The key is reducing the number of penetrations without compromising load capacity.

That’s precisely where next-generation systems like the Hitch Cladding Attachment System redefine performance.

Developed by Longboard Products and represented in Québec by Constrio, Hitch is a precision-engineered anchoring system designed to support heavy façades while preserving the continuity of insulation. Unlike conventional clip grids spaced at 24″ × 16″, Hitch achieves larger spans of 48″ × 32”, cutting the number of anchors nearly in half. Fewer penetrations mean fewer thermal bridges, faster installation, and a dramatic improvement in the overall efficiency of the wall assembly.

Certified by the Passive House Institute and manufactured entirely in North America, Hitch delivers up to 94% thermal efficiency. Its telescopic brackets provide up to one inch of on-site adjustment for uneven substrates and can accommodate insulation up to 16 inches thick, supporting wall assemblies with effective R-values exceeding R-60.

The difference is more than numerical, it’s practical. Hitch not only minimizes the number of clips but also reduces the risk of workmanship errors and simplifies coordination between trades. Contractors appreciate its simplicity, architects value its flexibility, and energy consultants recognize its quantifiable impact on airtightness and thermal continuity. Every stakeholder benefit from a system that performs as intended, both thermally and structurally.

Energy efficiency today is no longer about adding layers of insulation; it’s about eliminating weaknesses in the chain. When every connection matters, the anchor system becomes the silent hero of the envelope. By maintaining continuous insulation, reducing penetrations, and improving constructability, high-performance façade anchors like Hitch represent a strategic investment in long-term building quality. They protect not only the building’s energy balance but also its comfort, durability, and architectural integrity.

Ultimately, the success of an energy-efficient building lies not just in what we see, the cladding, the windows, the insulation, but in what we don’t: the precision of the systems that hold it all together. Hidden behind every beautiful façade, should be a high-performance anchoring system that keeps the building performing at its best for decades to come.

Learn more: contact Anna Vetter / avetter@constrio.com