Finishes

Designed to Perform

High Performance Aluminum Finishes

With over two decades of experience, Longboard is a premier producer of sustainable, durable, and visually striking powder-coated and sublimated extruded aluminum products. Our finishes adhere to the most stringent environmental guidelines to ensure the highest-quality product is delivered to our clients.

We use powder coating and sublimation methods for their durability and environmentally friendly properties. All of our finishes are AAMA 2604 or 2605 certified and undergo extensive in-house testing to ensure high performance.

From Our In House Palette to Custom Creations - The Perfect Finish Starts Here

Finishes

Most Popular Finishes

(Ready to ship within 2 weeks for orders less than 15k sq.ft)

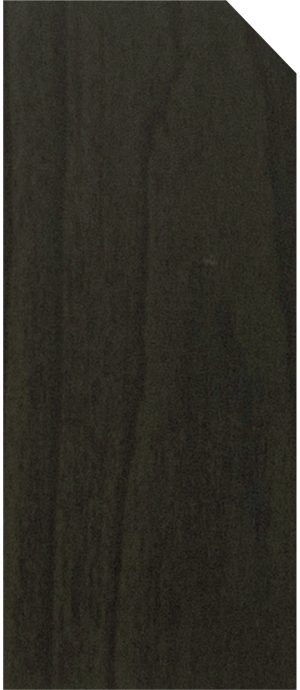

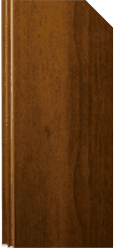

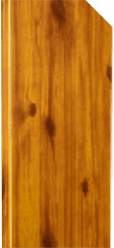

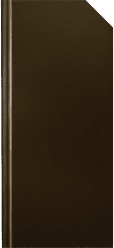

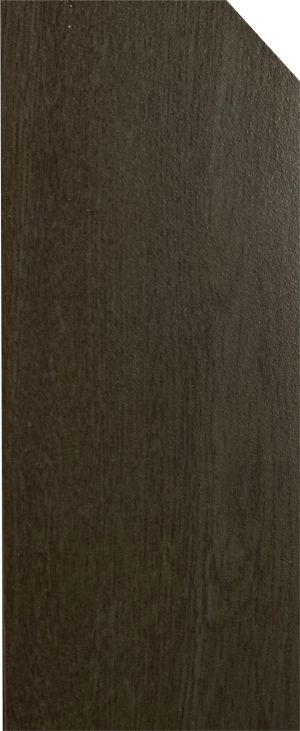

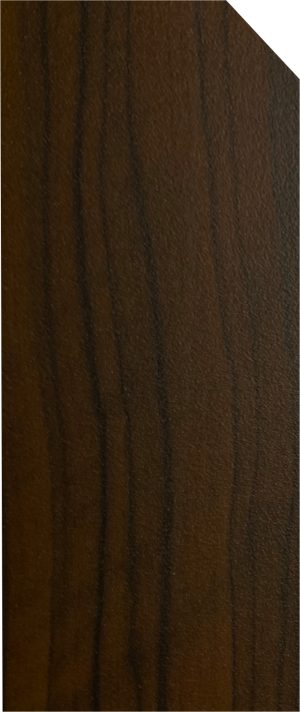

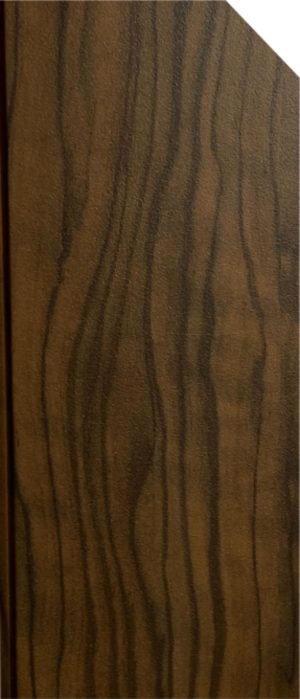

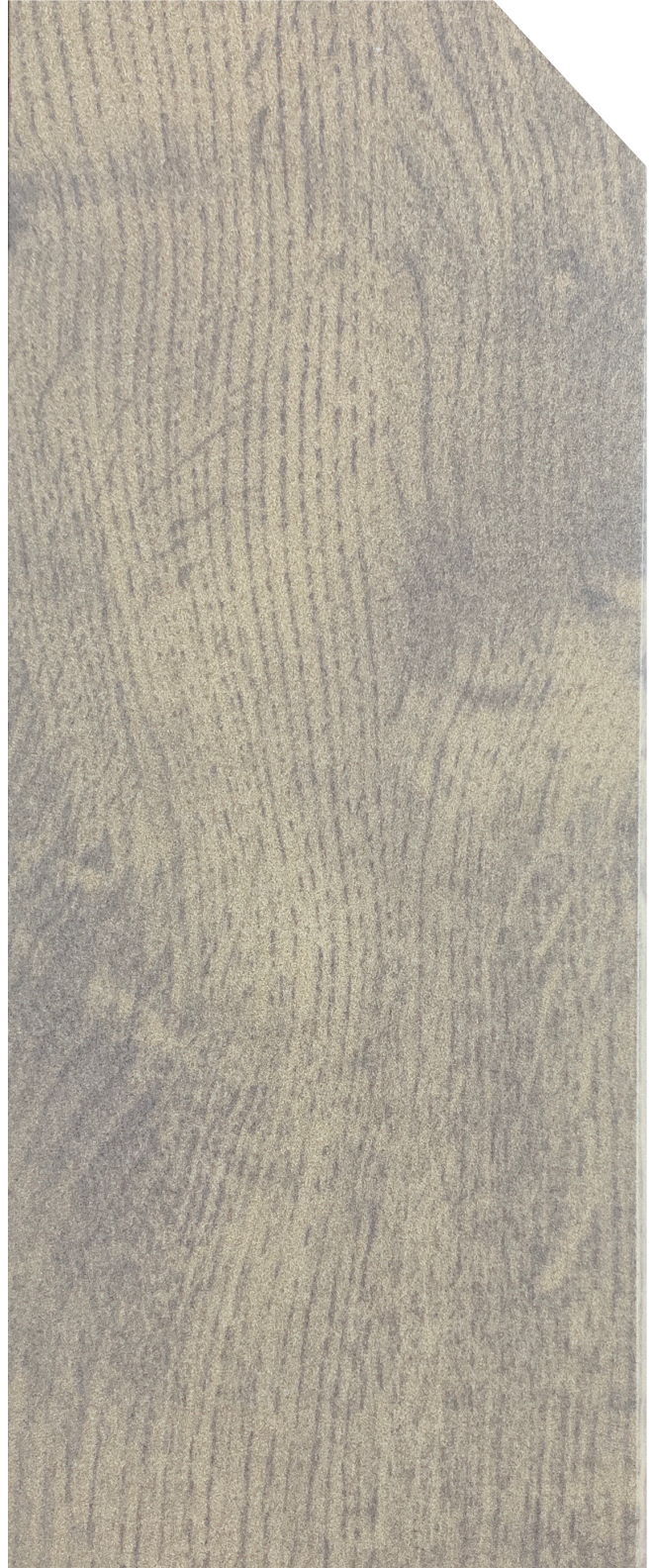

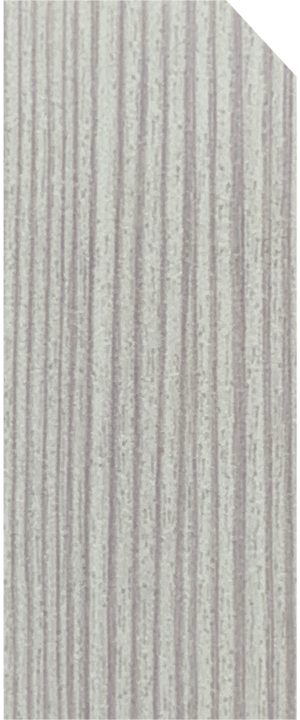

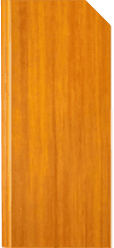

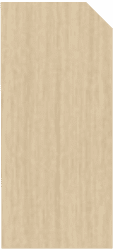

Woodgrains

Longboard's woodgrain finishes have a slight texture with a matte sheen.

Dark Bamboo

DBB

Light Bamboo

LBB

Dark Fir

DFR

Light Cherry

LCY

Light Fir

LFR

Rock Elm

REM

Blonde Oak

BOK

Beechwood

BEE

Birchwood

BWD

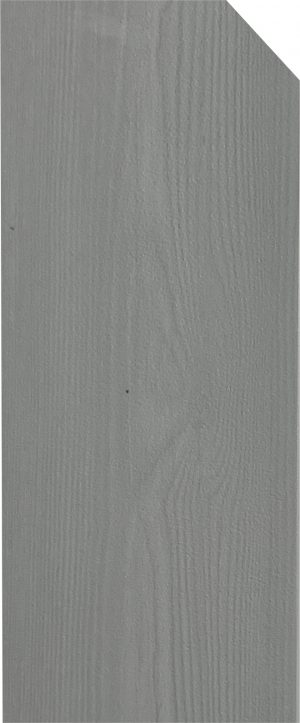

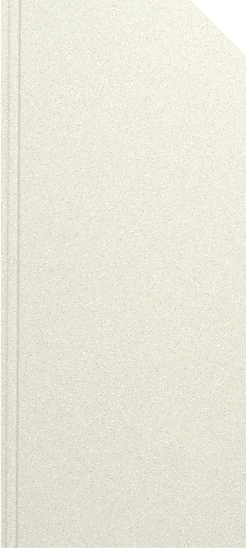

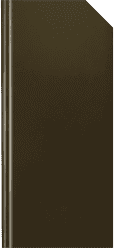

Solid & Specialty

Onyx Black

OBL

Textured Matte

Solid

Old Navy

ONA

Textured Matte

Solid

Textured Matte

Solid

Shale

SHA

Textured Matte

Solid

Smooth Satin

Solid

Dark Brown

DBR

Smooth Satin

Solid

Slate Grey

SGR

Smooth Satin

Solid

Venus

VEN

Smooth Satin

Metallic

Ultra White

UWH

Smooth Satin

Solid

Bone White

BWH

Smooth Satin

Solid

Additional Finishes

(Contact a Sales Rep for Lead Times)

Woodgrains

Longboard's woodgrain finishes have a slight texture with a matte sheen.

Solid & Specialty

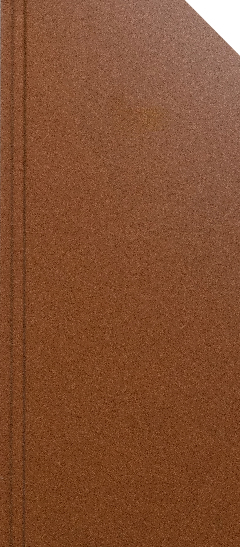

Speckle

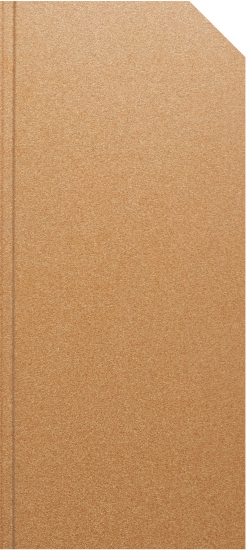

Brownstone

BST

Textured Matte

Speckle

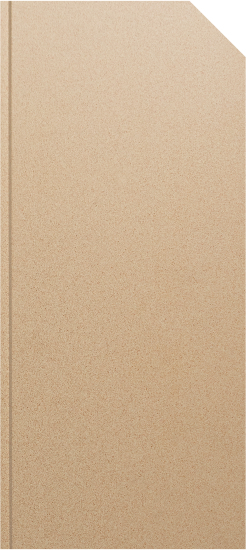

Baked Clay

BCL

Textured Matte

Speckle

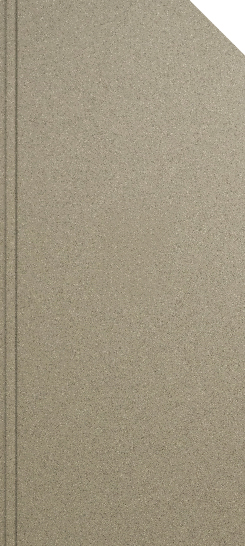

Burnt Sienna

BSN

Textured Matte

Speckle

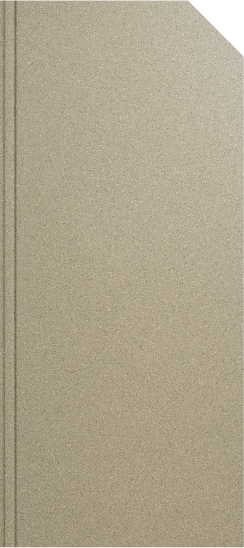

Biscotti

BIS

Textured Matte

Speckle

Relicstone

RST

Textured Matte

Speckle

Limestone

LST

Textured Matte

Speckle

Bedrock

BRK

Textured Matte

Speckle

Pebble

PEB

Textured Matte

Speckle

Alabaster

ALB

Textured Matte

Speckle

Textured Matte

Speckle

Naturally Aged Metals

Liberty

LIB

Textured Matte

Naturally Aged Metals

Empire

EMP

Textured Matte

Naturally Aged Metals

Brooklyn

BRO

Smooth Glossy

Naturally Aged Metals

Eiffel

EIF

Textured Matte

Naturally Aged Metals

Golden Gate

GGA

Textured Matte

Naturally Aged Metals

Your screen, and our pictures do not accurately reflect aspects of our finishes – textures, sheen, woodgrain hues, etc. Always order a physical sample before purchase!

Contact us to confirm lead times for orders greater than 15k sq.ft in the Most Popular Finishes category.

Longboard Finish Classification�

Type: Woodgrain / Solid / Metallic /

Speckle / Naturally Aged Metal

Surface: Smooth / Textured

Sheen: Matte / Satin / Glossy

Performance: AAMA 2604 / AAMA 2605

Finish Warranty: 15 Year / 20 Year

Longboard is a certified AAMA 2604 and AAMA 2605 applicator and has adopted the AAMA 2604 performance standard as a minimum threshold for any of its exterior finishes and product offerings.

Our facilities are regularly subjected to inspections and audits to ensure continuous compliance with these performance standards.

These standards measure the coating performance based on a variety of factors including:

- Color uniformity and gloss

- Coating thickness and hardness

- Adhesion of the coating to the metal substrate

- Impact, abrasion and chemical resistance

- Humidity and salt spray corrosion resistance

- Weathering resistance with regards to color and gloss retention, erosion resistance and chalk resistance

As with solvent-based liquid coatings, a wide range of alternative chemistries and application procedures are available to the applicator which enables an optimum match to be achieved between the properties of the powder coating and the performance demands in service.

Significant advancements have been made in powder coating technology and these finishes are both technically and environmentally sustainable alternatives to liquid polyvinylidene fluoride (PVDF) and fluoroethylene vinyl ether (FEVE) systems. When specifying a powder coating finish for any architectural application it is essential to select the correct type of powder and the correct application procedures to ensure that the optimum performance is obtained.

For many years the architectural community in North America has referenced the AAMA (American Architectural Manufacturer’s Association) standards for the testing and performance of organic coatings on architectural aluminum extrusions and panels. AAMA developed three standards by which architects and designers can identify the differences between finish performance on metals:

- AAMA 2603 – Good performance

- AAMA 2604 – High performance

- AAMA 2605 – Superior performance

| Coating Systems | Performance Standard | Finish Warranty |

|---|---|---|

| Solid Color Finishes - Ultra Durable Polyester Powders | AAMA 2604 | 15 Year Non-prorated |

| Solid Color Finishes - Hyper Durable Fluoropolymer Powders | AAMA 2605 | 20 Year Non-prorated |

| Woodgrain & Speciality Finsihes - Ultra Durable Polyurethane Powders & Sublimation Inks | AAMA 2604 | 15 Year Non-prorated |

| Woodgrain & Speciality Finishes - Hyper Durable Polyurethane Powders & Sublimation inks | AAMA 2605 | 20 Year Non-prorated |

Achieve your Vision!

Order a physical sample or colour bar to view the most accurate representation of our finishes.

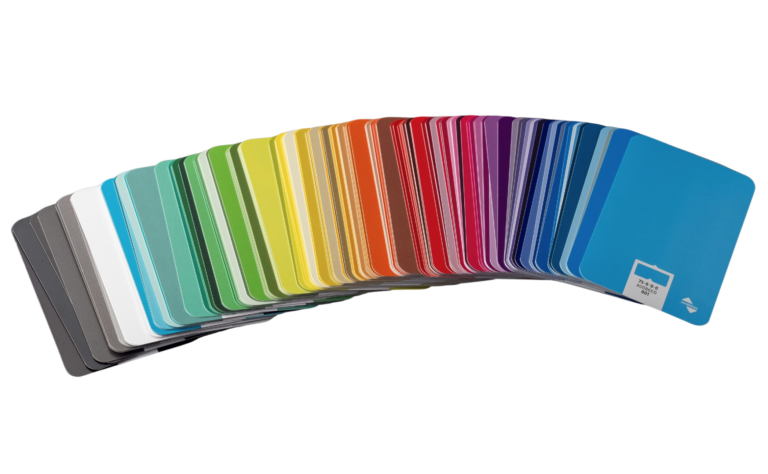

Custom Color Matching

Custom colors are an excellent choice for projects that demand a personalized touch and a distinct visual impact, whether the application is institutional, commercial, healthcare-related, or residential. These finishes offer a level of design flexibility and creative freedom that allows architects, designers, and homeowners to bring their unique visions to life with precision and flair. We proudly collaborate with top-tier coating suppliers in the architectural finishes industry to ensure every custom color meets the highest standards of uniqueness, durability, and sustainability.

Once a potential color match is identified, all custom finishes are subjected to thorough testing protocols, including evaluations for corrosion resistance, UV stability, and long-term weathering performance. These tests are crucial to ensure that custom finishes retain their appearance and structural integrity over time, even in the face of harsh environmental conditions.

This disciplined approach to powder coating, combined with our stringent quality and process control standards, is what sets us apart as a trusted industry leader. Our commitment to excellence ensures that every custom color finish we produce not only looks beautiful at installation but continues to perform at a premium level for many years to come.

LB RAL Classic Solid Colors

The most efficient and reliable method for color matching we offer is through our RAL Classic color matching program. This internationally recognized, standardized system includes a carefully curated palette of over 200 colors, ranging from timeless neutrals like crisp whites and deep blacks to vibrant hues such as vivid yellows, striking reds, and rich violets. Because RAL colors are universally standardized, they ensure consistency across projects and manufacturing runs, regardless of location or application.

One of the major advantages of using RAL is the elimination of the need for physical sample chips in the early stages of selection. This streamlines the approval process, significantly reduces lead times, and eliminates much of the back-and-forth often associated with custom color matching. As a result, clients benefit from greater speed, convenience, and cost-effectiveness without compromising on quality or precision.

To explore the range of RAL options available, we recommend browsing the full RAL Classic color chart online. For those who prefer a tactile reference, our physical fan deck is also available for purchase through our online store. Utilizing the RAL system is a smart, efficient choice for projects requiring dependable color accuracy and faster turnaround times.

|

|

Solid Non-Metallic

|

Solid Metallic / Speckle

|

Woodgrain/Naturally Aged Metal

|

|---|---|---|---|

|

Processing Charge |

$500 |

$500 |

$500 |

|

Color Match via |

|

Client Provided Samples |

Client Provided Samples |

|

Custom Color Sample |

3-5 Weeks |

Up to 5 Weeks |

Up to 8 Weeks |

|

Full Production |

Up to 8 Weeks |

Up to 8 Weeks |

Up to 12 Weeks |

|

Minimum Order |

|

|

|

View Examples

Custom Color Projects

Your project deserves a finish unique to your design !

Speak with our sales team to explore tailored color solutions or to discuss & order our new RAL Custom Color Deck.