Content Type:

-

Project Type:

-

System Name:

-

Installation:

-

In recent years, sustainability has become a key focus for businesses across various industries, and the manufacturing sector is no exception. Manufacturing activities consume vast amounts of energy and water, generate substantial waste, and contribute to pollution and greenhouse gas emissions. By embracing sustainable practices, manufacturers can minimize their ecological footprint and reduce the impact the sector has on the environment.

Governments and regulatory bodies are attempting to speed up this process by imposing stricter environmental regulations and standards. Non-compliance can result in hefty fines, legal repercussions, and damage to a company’s reputation.

To combat and appeal to the above rules, manufacturers are increasingly adopting practices that optimize the use of energy, water, and raw materials. This includes implementing energy-efficient technologies, using recycled materials, and reducing waste generation. By minimizing resource consumption, manufacturers can lower their carbon footprint and contribute to a more sustainable manufacturing process. Reducing waste generation and promoting recycling are crucial elements of sustainable manufacturing. These efforts not only contribute to a circular economy but also help conserve natural resources and reduce the strain on landfills.

(The concept of a circular economy drives companies to design products that can be recycled, refurbished, or repurposed at the end of their life cycle. This reduces the demand for new resources.)

Manufacturers can:

- Consider transitioning to renewable energy sources like solar, wind, or geothermal power to reduce reliance on fossil fuels.

- Implement waste reduction strategies, such as lean manufacturing principles and encourage recycling.

- Adopt water-saving technologies and practices to reduce water consumption, consider water recycling systems.

- Develop responsible disposal practices for waste and hazardous materials to prevent environmental pollution.

- Involve employees in sustainability initiatives and encourage their participation in finding innovative ways to reduce waste, conserve resources, and improve overall sustainability within the company.

Sustainability in manufacturing extends beyond the factory walls and encompasses the entire supply chain. Manufacturers are now actively engaging with suppliers and partners who share their commitment to sustainable practices. This includes selecting suppliers with eco-friendly policies, encouraging sustainable packaging solutions, and optimizing transportation routes to minimize emissions.

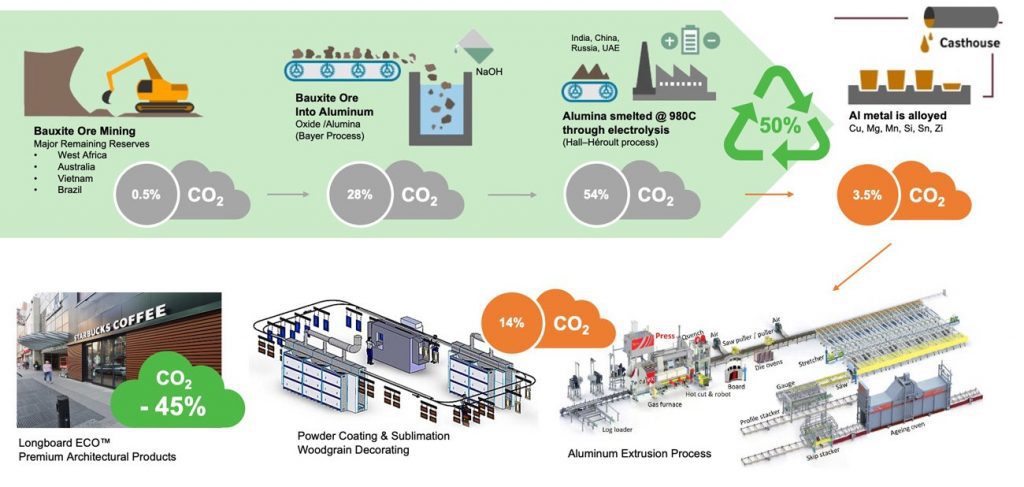

Manufacturers are also starting to adopt life cycle assessment (LCA) tactics to evaluate the environmental impact of their products at every stage, from raw material extraction to end-of-life disposal. By analyzing the life cycle of a product, manufacturers can make informed decisions that prioritize sustainability and create greener, more eco-friendly products. A company may discover that there are more sustainable materials available, energy consumption during production could be reduced, or their wastewater could be filtered more efficiently.

Today’s consumers are more environmentally conscious and socially responsible in their purchasing decisions. They actively seek out products that align with their values, including those manufactured sustainably. By incorporating sustainable practices, manufacturers can meet consumer expectations, enhance their brand reputation, and gain a competitive edge in the market.

Demonstrating a commitment to sustainability can attract a broader customer base and build brand loyalty among environmentally conscious consumers. Sustainability-focused initiatives can also attract collaborations, partnerships, and funding from organizations and investors that prioritize sustainable business models.

If the industry doesn’t improve and adopt more sustainable practices, there could be severe consequences. Without a focus on sustainability, the manufacturing industry will continue to contribute to environmental degradation. Increased resource consumption, waste generation, and pollution levels will accelerate the depletion of natural resources, exacerbate climate change, and harm ecosystems. The result would be a further decline in air quality, water scarcity, loss of biodiversity, and other ecological imbalances. Failing to address these issues could lead to irreversible damage to the environment, impacting not only the planet but also human health and well-being.

By prioritizing sustainability, the manufacturing industry can lead the way in creating innovative solutions that balance environmental stewardship with economic growth.

Explore Longboard ECO™

Frequently Asked Questions

How do consumers influence the adoption of sustainable practices in the manufacturing industry?

Consumers play a pivotal role in pushing the manufacturing industry toward sustainability by preferring products that are eco-friendly, which, in turn, motivates companies to adopt green practices.

What specific challenges do manufacturers face when transitioning to more sustainable production methods?

Manufacturers transitioning to sustainable methods often face challenges like high initial costs, lack of technology, and the need for skilled labor.

What are examples of companies that have successfully implemented sustainable manufacturing practices?

Companies like Patagonia, Tesla, and IKEA are notable for their sustainable manufacturing practices. Patagonia focuses on environmental responsibility, Tesla pioneers in electric vehicles and clean energy, while IKEA commits to renewable materials and energy efficiency. These firms illustrate successful sustainable approaches in various industry sectors.