Content Type:

Case Study, Installation, Performance & Testing

Project Type:

Building, Single Family

System Name:

Hitch™, Link & Lock™, T&G Planks

Installation:

Exterior

On This Page ▶

- Introduction to Passive House

- Project Details

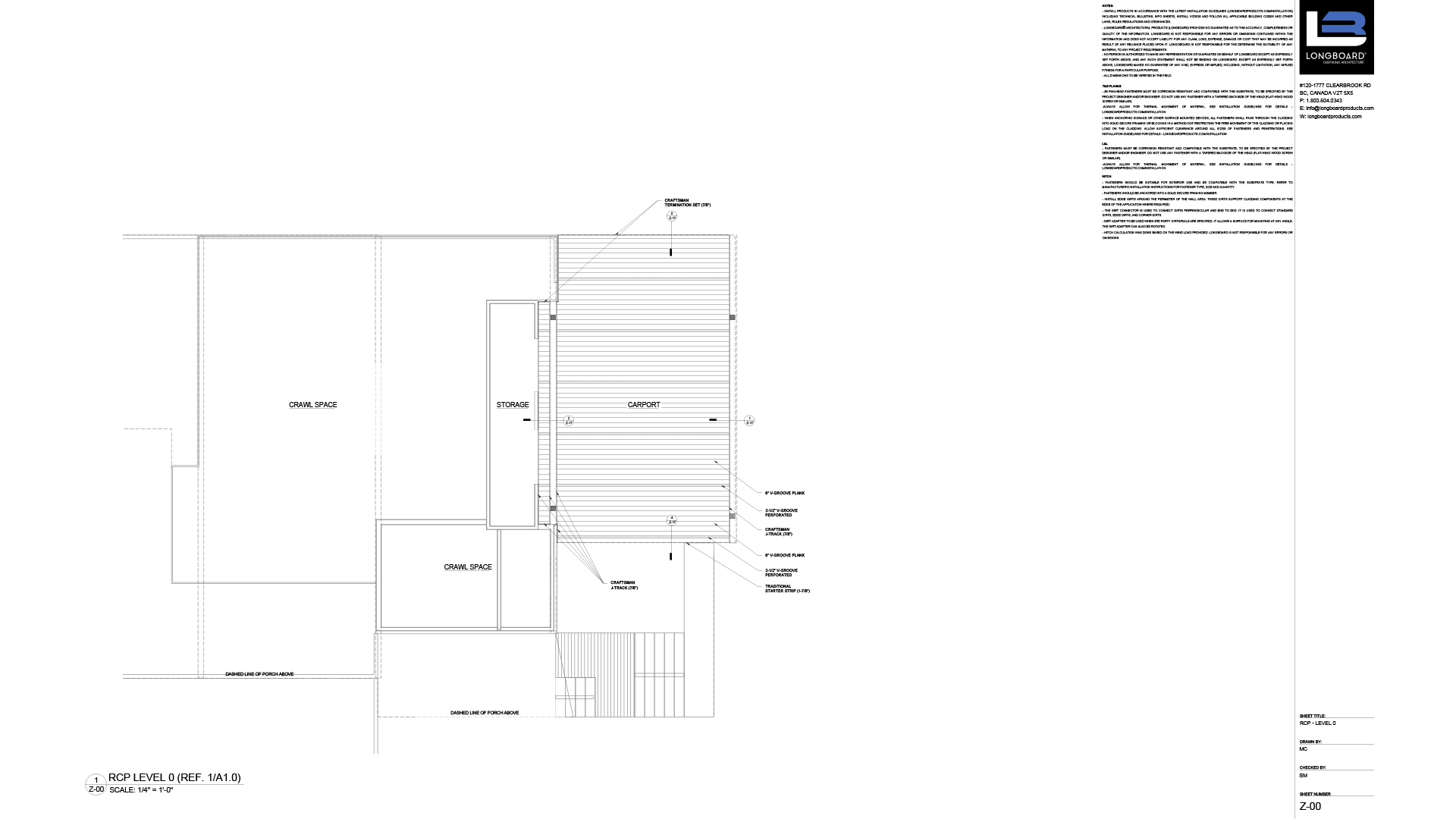

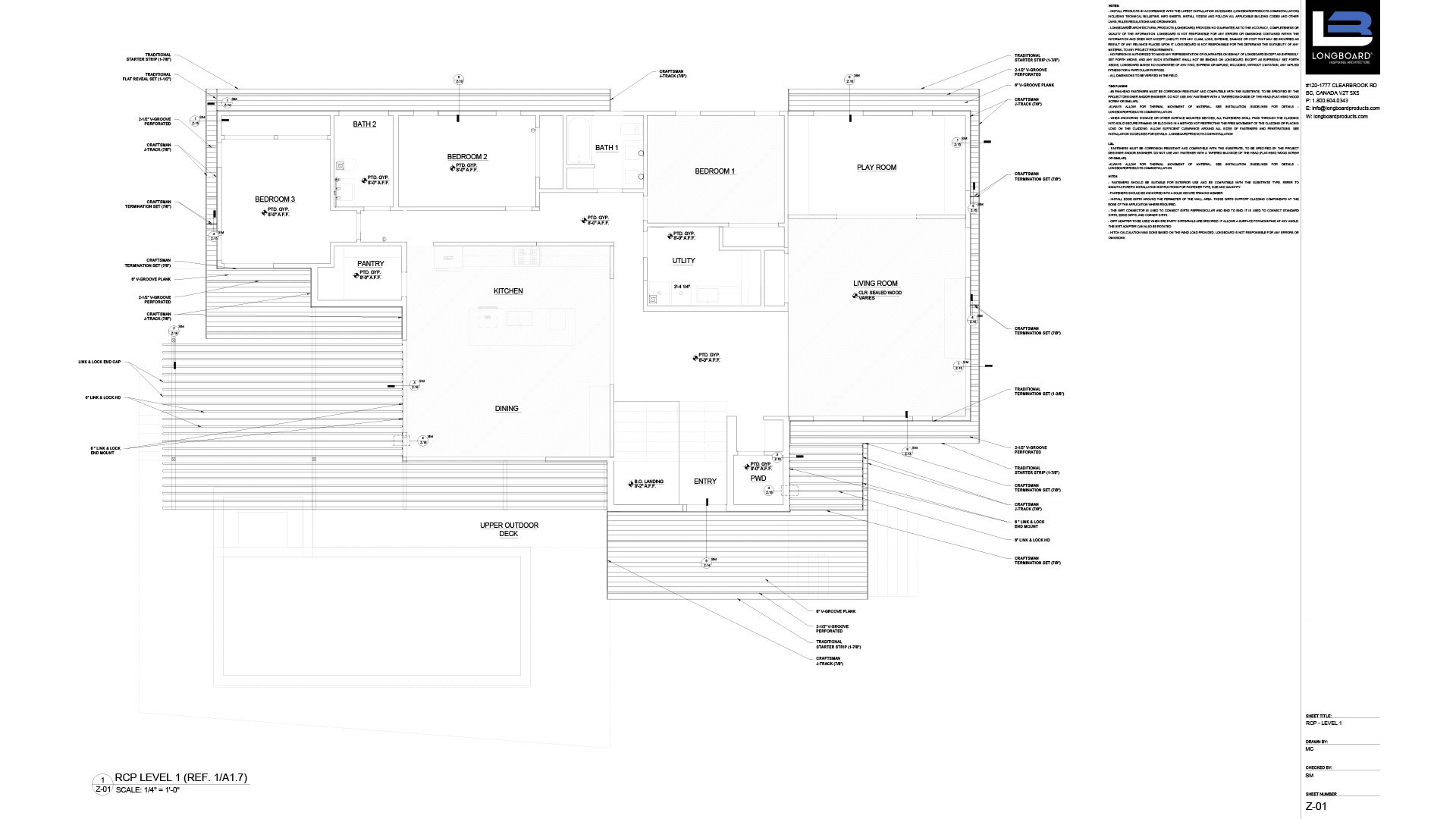

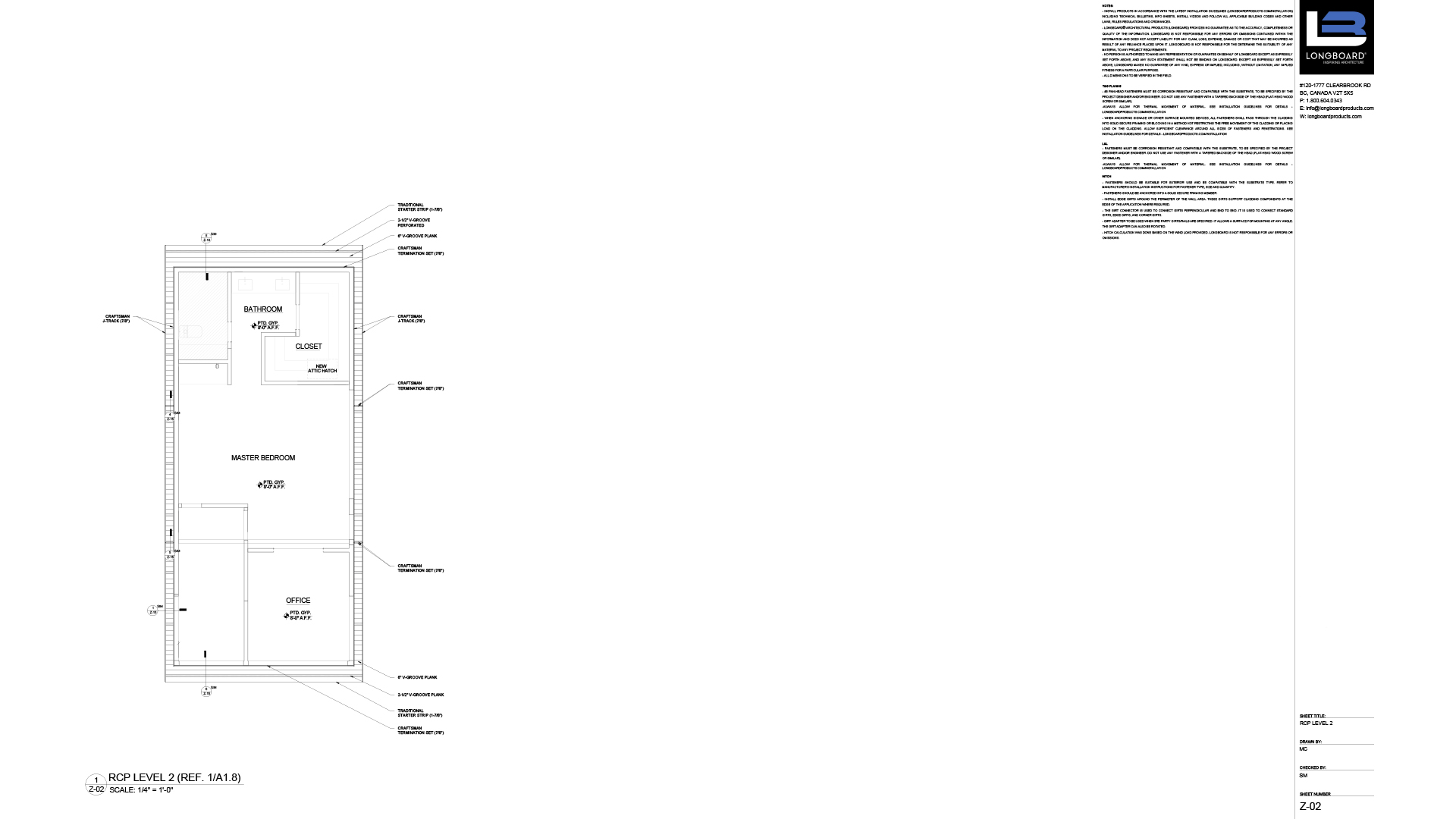

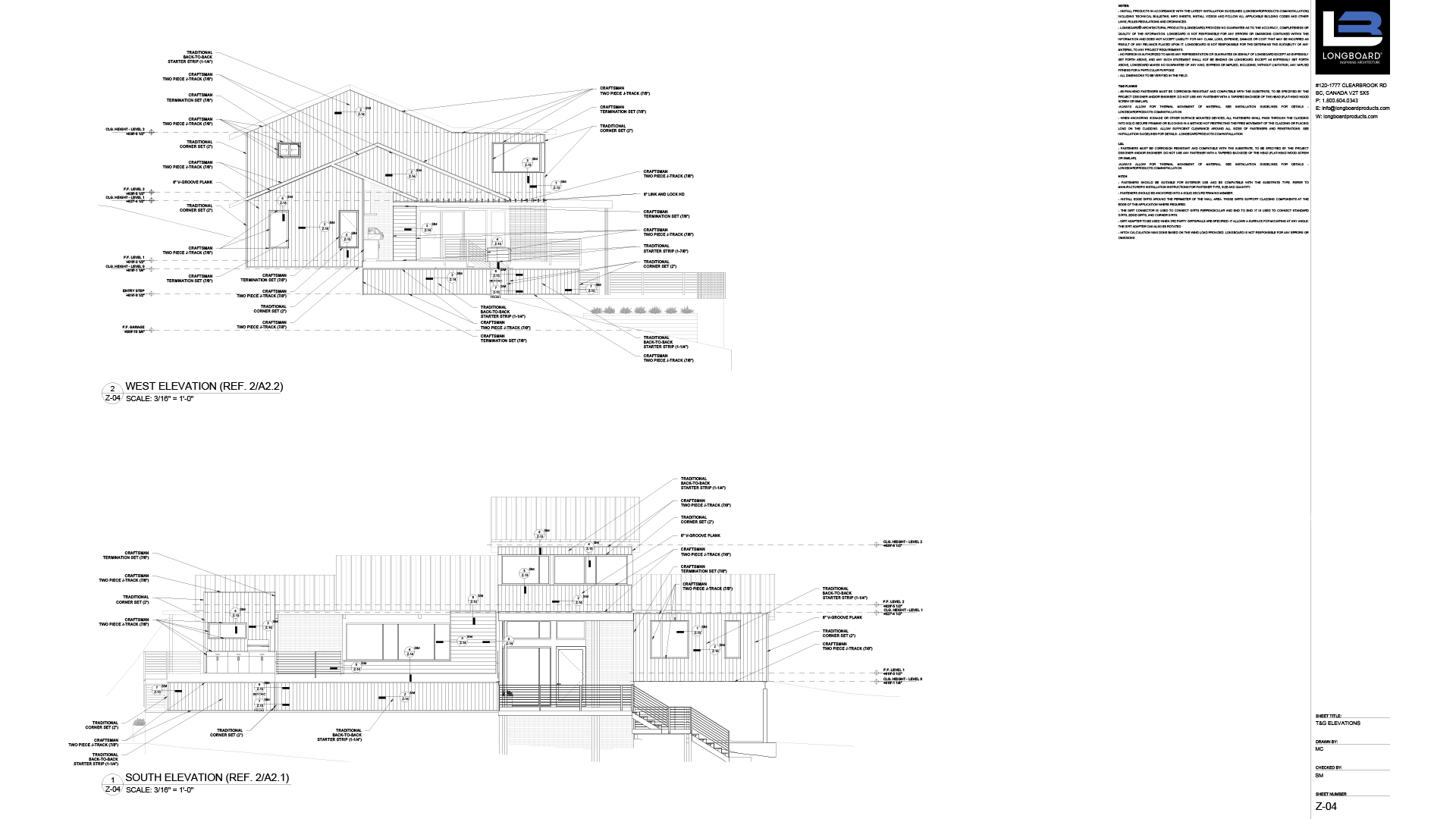

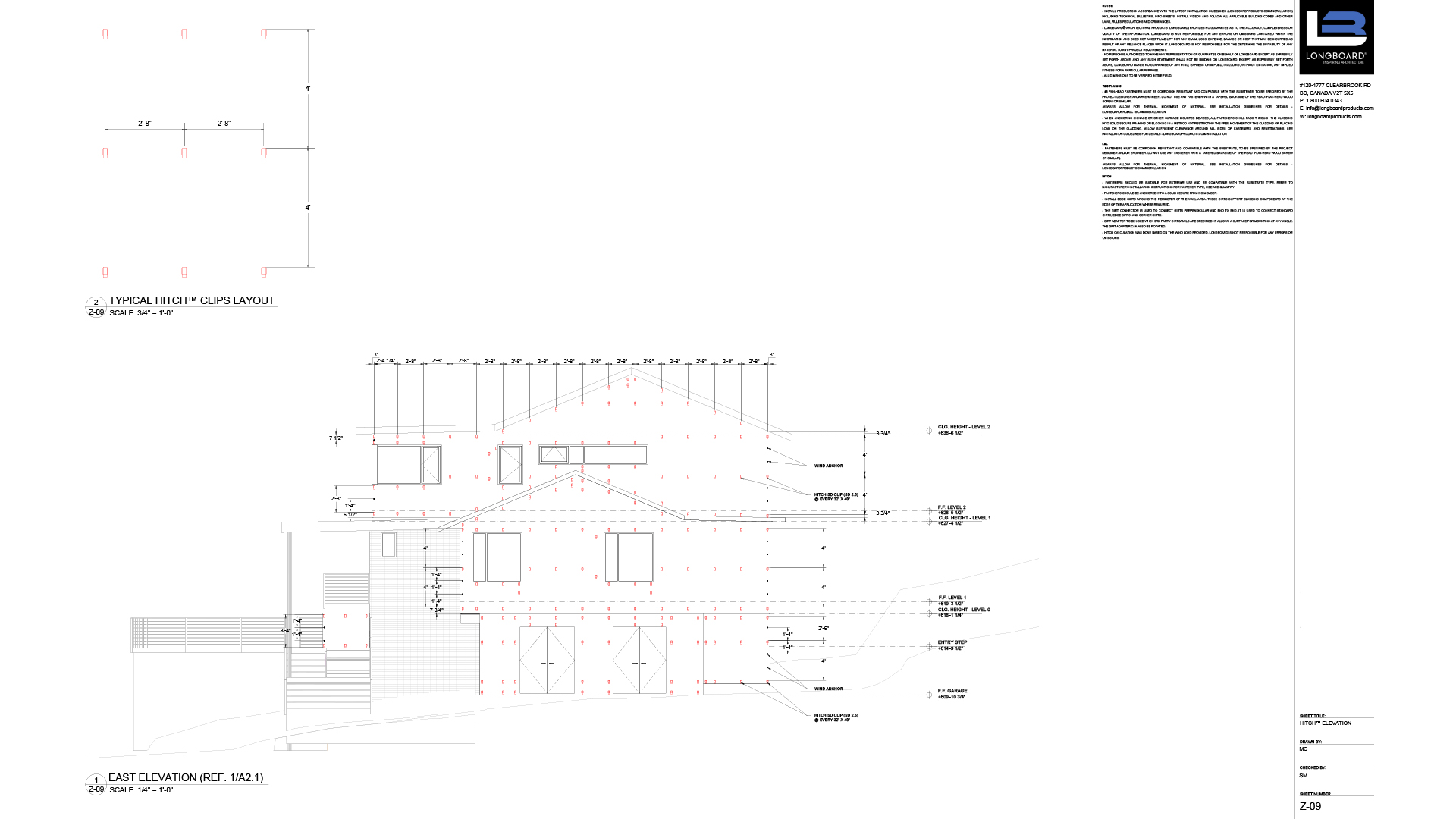

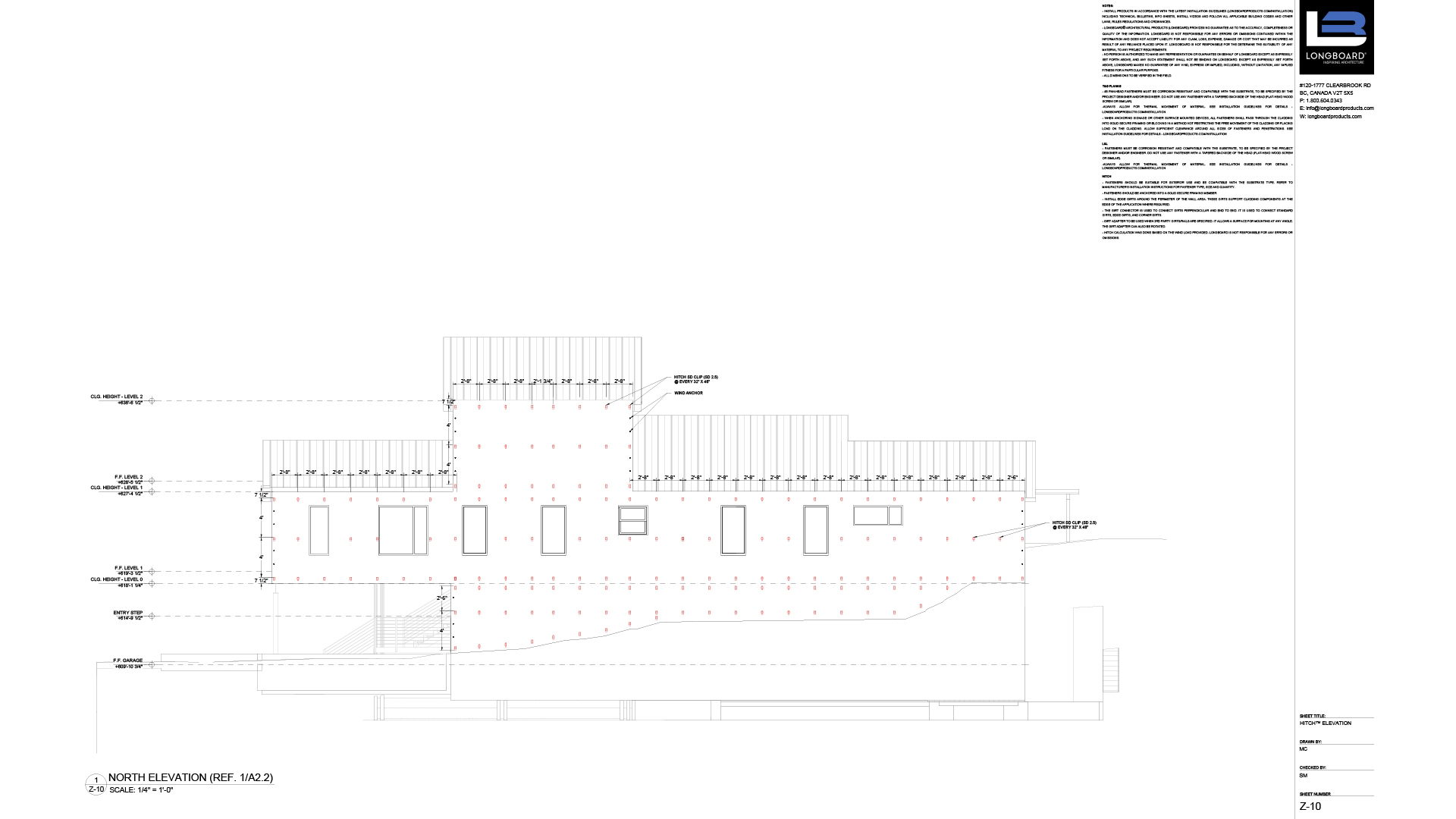

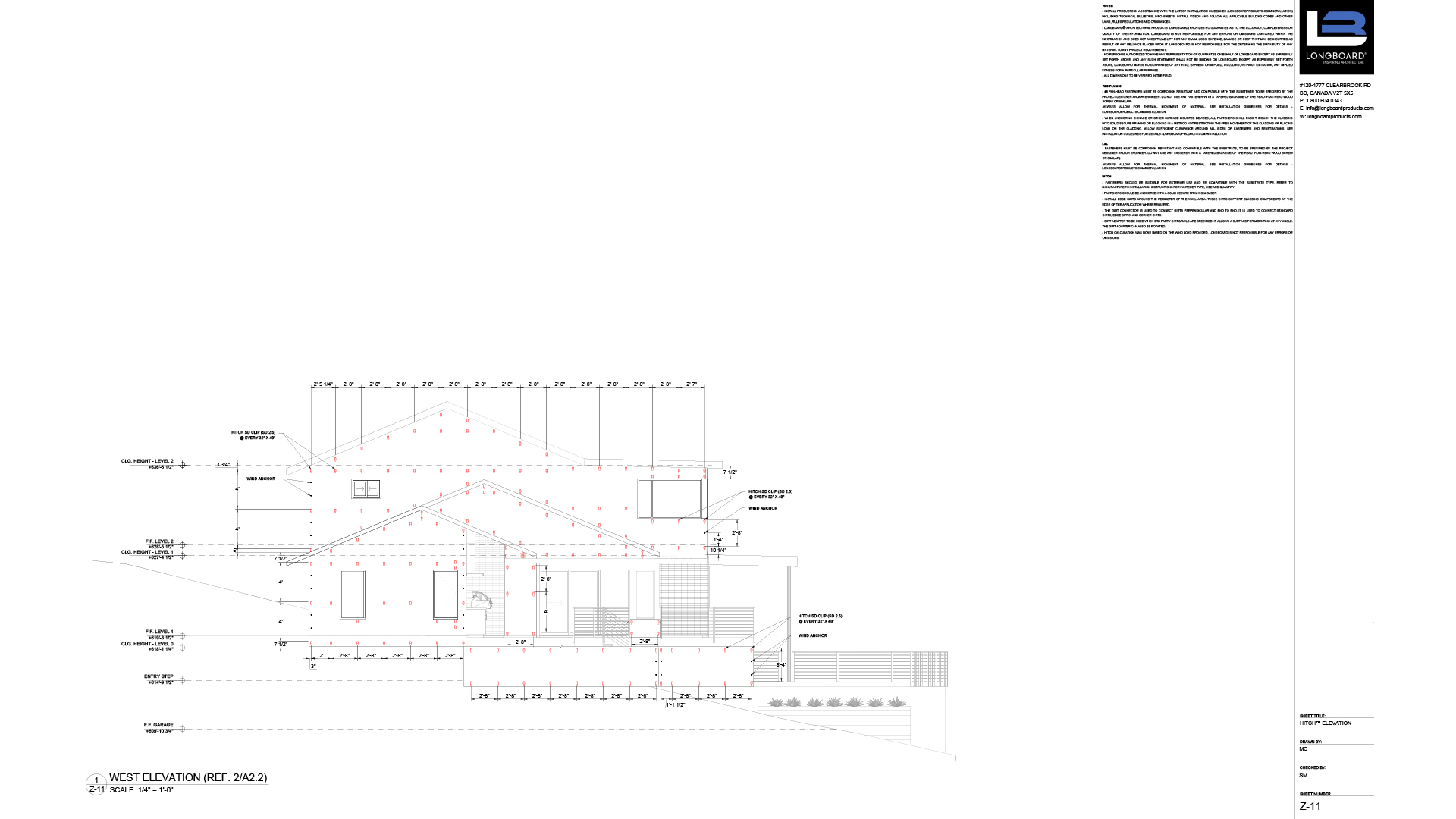

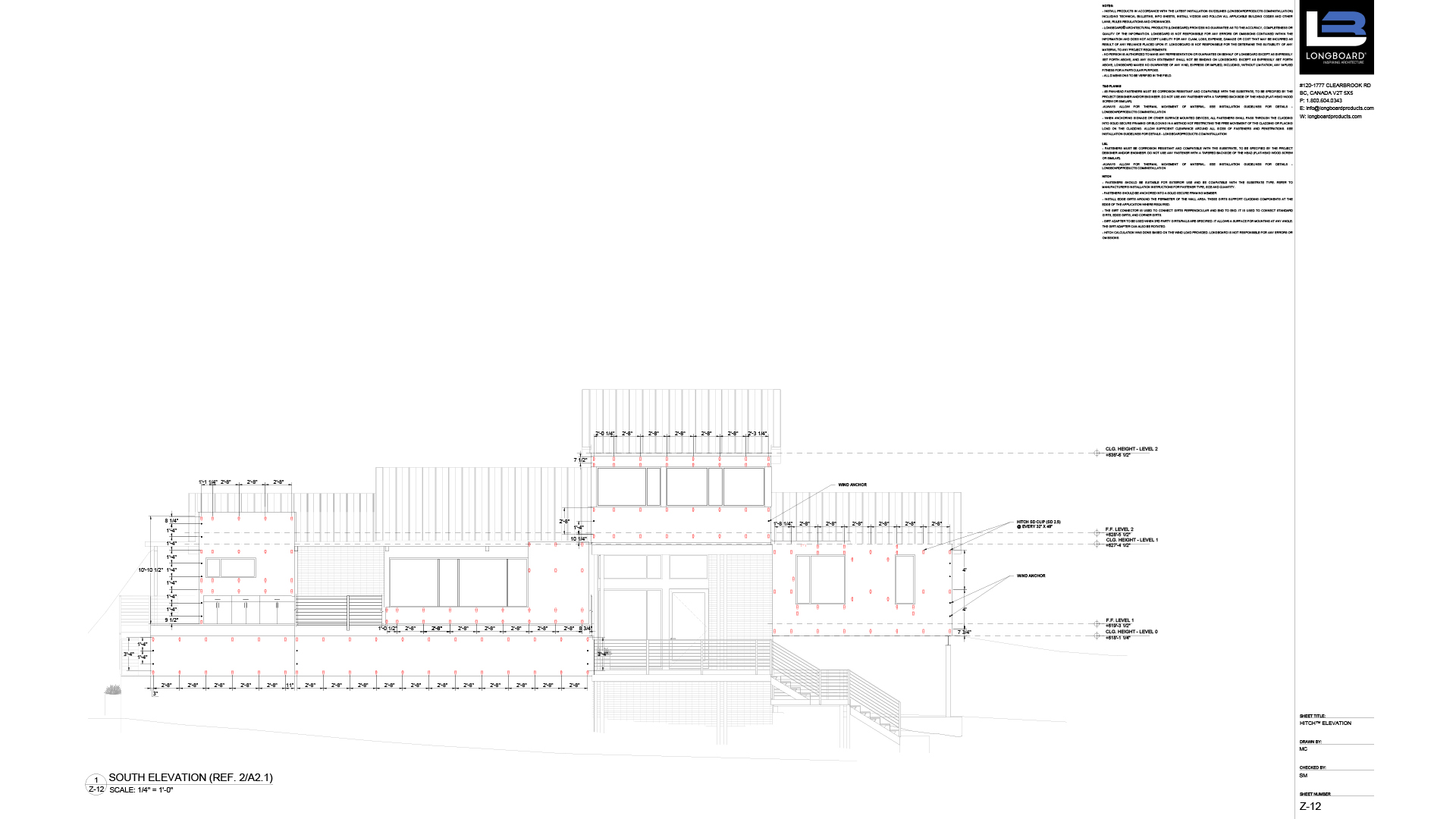

- Shop Drawings and Customization

- Installation Process

- Project Gallery

- Closing Thoughts

- About Longboard Architectural Products

In early 2024, Daniel Glauser, a key member of the BUILD Show team, took on an extensive renovation of his 1970s-era home. Drawing on his expertise in high-performance construction, Daniel transformed his family’s residence into a state-of-the-art dwelling that exemplifies the core principles of sustainable renovation. His passion for energy efficiency and the Passive House standard made this project not just a home update, but a model of modern renovation practices. As both a resource and an ambassador for building science, Daniel’s knowledge significantly contributed to the project’s success, making this renovation a true testament to the potential of high-performance homes.

Daniel and his family had lived there for nearly four years before deciding to renovate, driven by their desire to improve the home’s energy efficiency and overall comfort. Undertaking the renovation while living in the house posed some unique challenges, requiring a well-planned, phased approach.

The goals of the project were ambitious: to create a contemporary, sustainable home using the latest in building science technology, all while maintaining the family’s day-to-day living activities. The project sought not only to improve thermal performance, but to also blend modern aesthetics with high-performance building systems.

Introduction to Passive House

For those new to building science, Passive House (or Passivhaus) is a rigorous, energy-efficiency standard that reduces a building’s environmental impact while enhancing indoor comfort. The core goal of Passive House design is to create structures that require minimal energy for heating and cooling, often achieving energy savings of up to 90% compared to conventional buildings. This high level of performance is achieved through a combination of airtight construction, advanced insulation, high-performance windows, and mechanical ventilation systems with heat recovery.

The Passive House concept was first developed in the late 1980s by Dr. Wolfgang Feist, a physicist, and Bo Adamson, a Swedish building scientist. Together, they set out to create a building standard that minimized energy usage while maximizing comfort. Their collaboration resulted in the construction of the first Passive House in Darmstadt, Germany, in 1991. This pioneering project demonstrated that a home could maintain a comfortable indoor temperature with little reliance on external energy sources, inspiring the creation of the Passivhaus Institut in 1996.

The Passive House standard quickly gained traction due to increasing concerns about energy costs, environmental impact, and the push for more sustainable living practices. Over time, the government and various municipalities began to offer incentives and subsidies for homes built to the Passive House standard, further accelerating its adoption. Passive House projects soon expanded beyond residential homes to include schools, office buildings, and public facilities. By the 2000s, it was widely recognized as a gold standard for energy efficiency in Germany and many other parts of Europe.

The standard made its way to North America in the early 2000s, thanks to the efforts of organizations like Passive House Canada and the Passive House Institute US (PHIUS). These groups worked to adapt the German-based standard to suit North America’s diverse climates and construction methods. As energy costs continued to rise and the focus on sustainability grew, the appeal of Passive House design expanded in the U.S. and Canada, particularly in regions with extreme weather conditions. The standard gained further momentum as architects, builders, and homeowners recognized the long-term cost savings and environmental benefits of Passive House-certified buildings.

Basic Principles of Passive House

The core principles of Passive House building in the U.S. are adapted to suit the diverse climate and construction practices found across North America. These principles aim to minimize energy usage while maximizing comfort and air quality. The Passive House Institute US (PHIUS) has outlined the following key principles that form the foundation of passive building:

These principles collectively enable Passive House buildings to achieve outstanding energy efficiency, comfort, and durability, making them suitable for various climates across North America

Project Details

Products: HITCH™ SD, 6″ V-Groove Planks, Link & Lock™ Architectural Battens

Finishes: Light National Walnut

Uses: Cladding Attachment, Cladding, Soffits, Architectural Feature

Architect: Designtrait Architects

Installer: Daniel Glauser & Team

Market: Residential

Year: 2024

The renovation of Daniel Glauser’s 1970s home aimed to dramatically improve its energy efficiency through Passive House principles, with a particular focus on thermal bridging mitigation and exterior insulation. Given the nature, scale and technical complexity of the project, Longboard was excited to partner with Daniel and the Build Show team. As advocates for Passive House design, we saw a natural synergy between the project’s goals and our products. This collaboration led to Longboard sponsoring part of the renovation, by contributing our HITCH™ system, Tongue & Groove Planks for the cladding and soffits, as well as our Link & Lock™ battens for a passive shade feature near the windows. Additionally, Longboard sponsored & participated in the Build Show’s YouTube coverage of the remodel, which highlighted both the design challenges and the energy performance enhancements of the project.

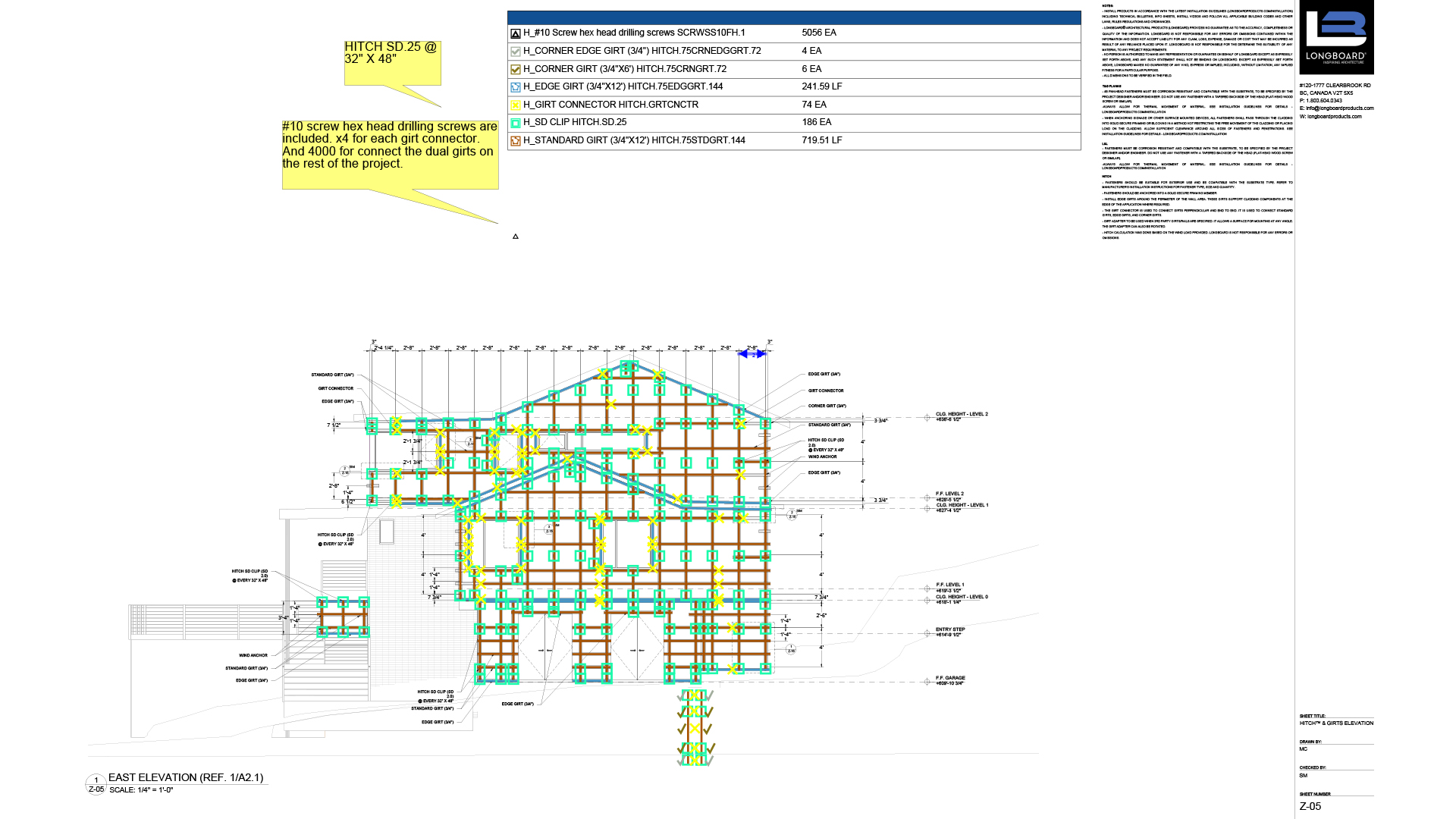

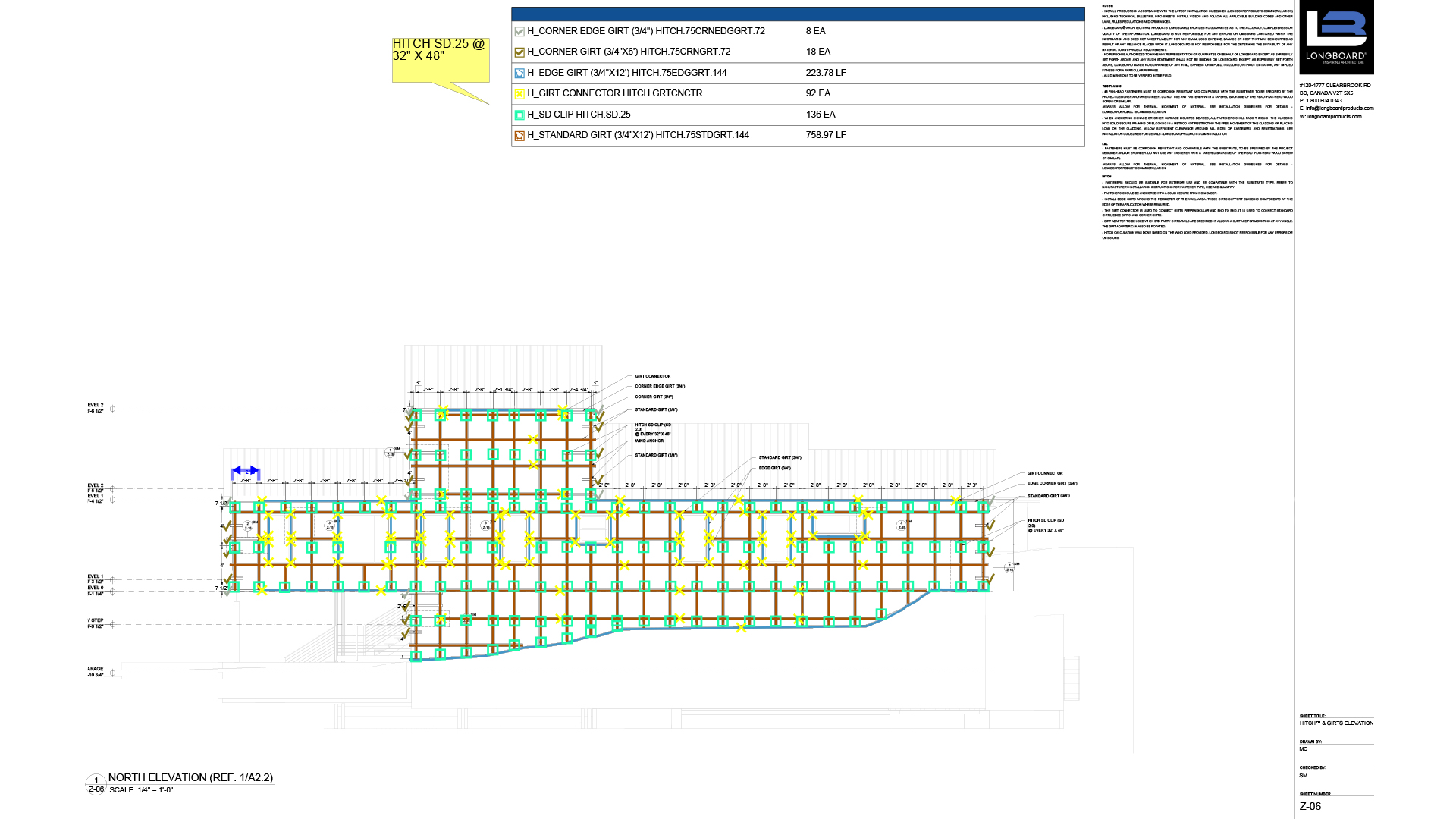

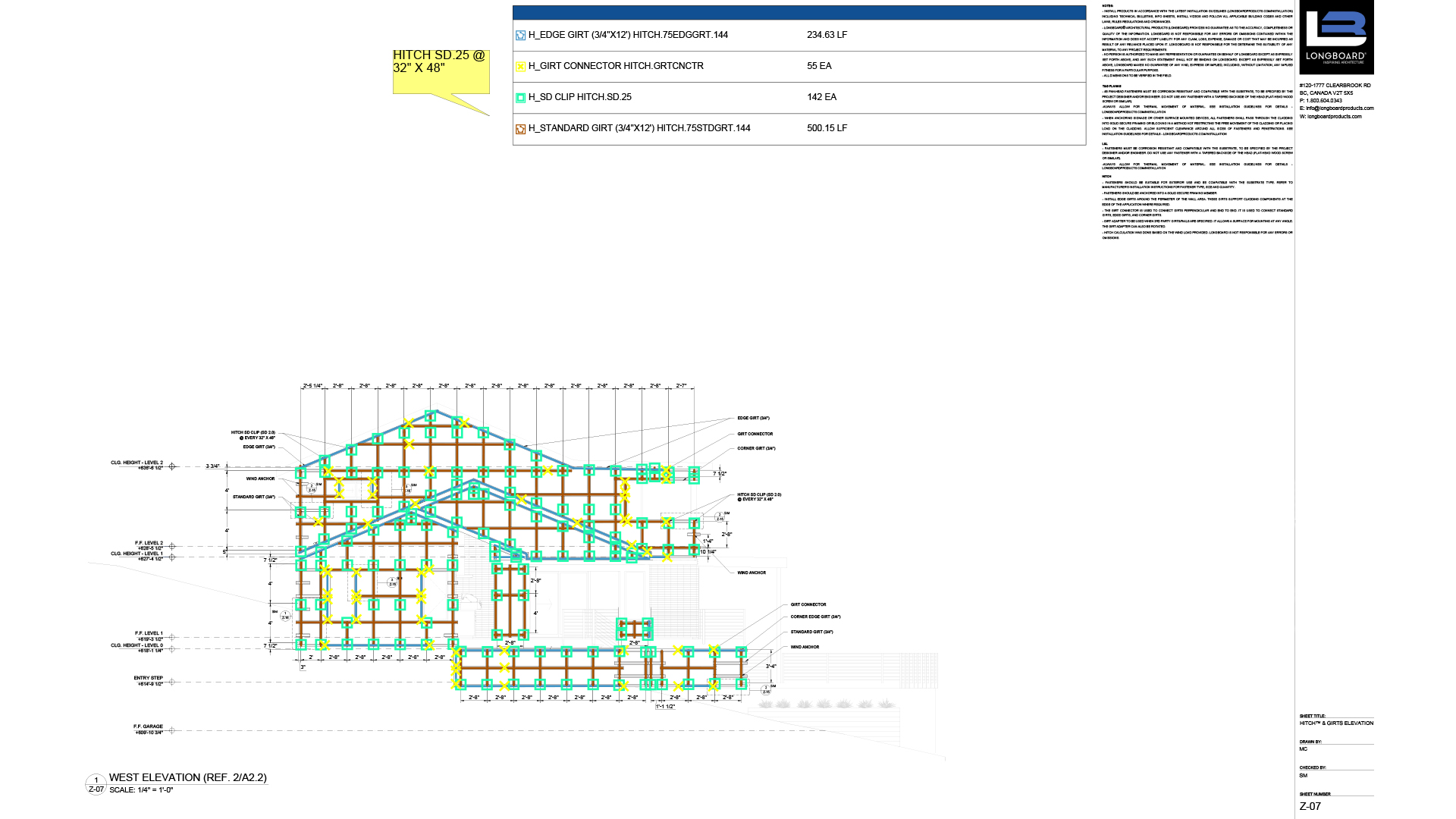

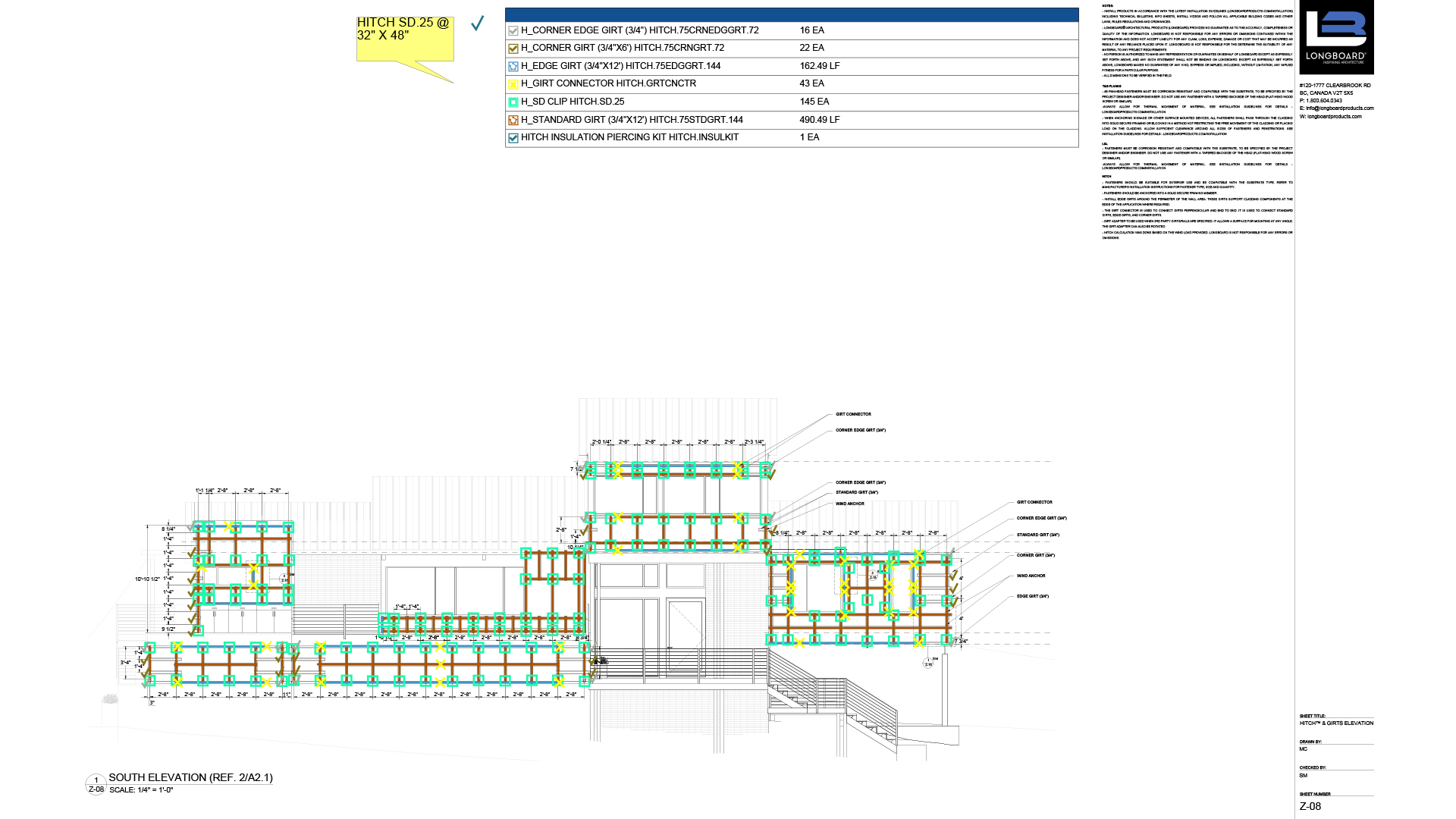

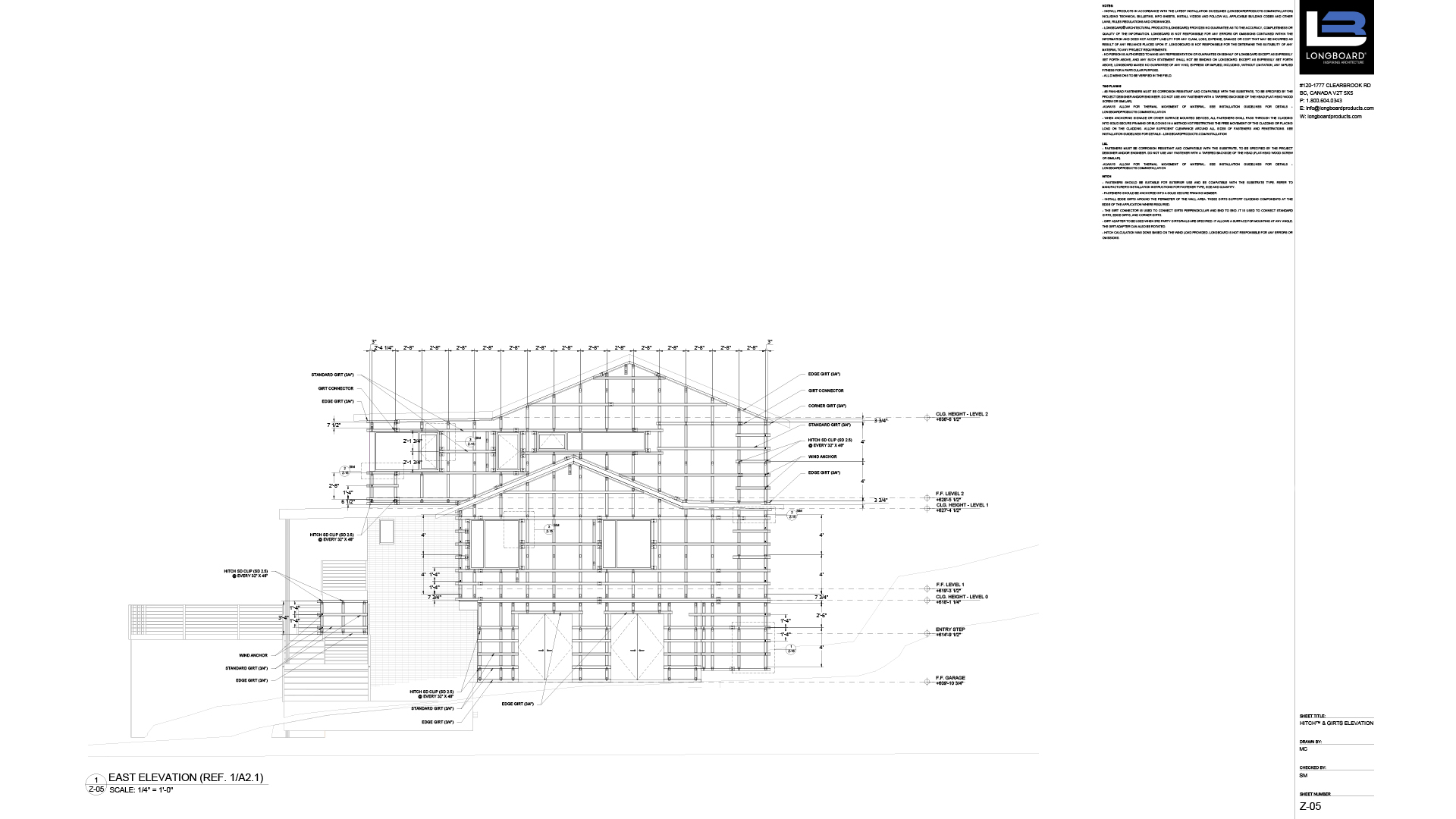

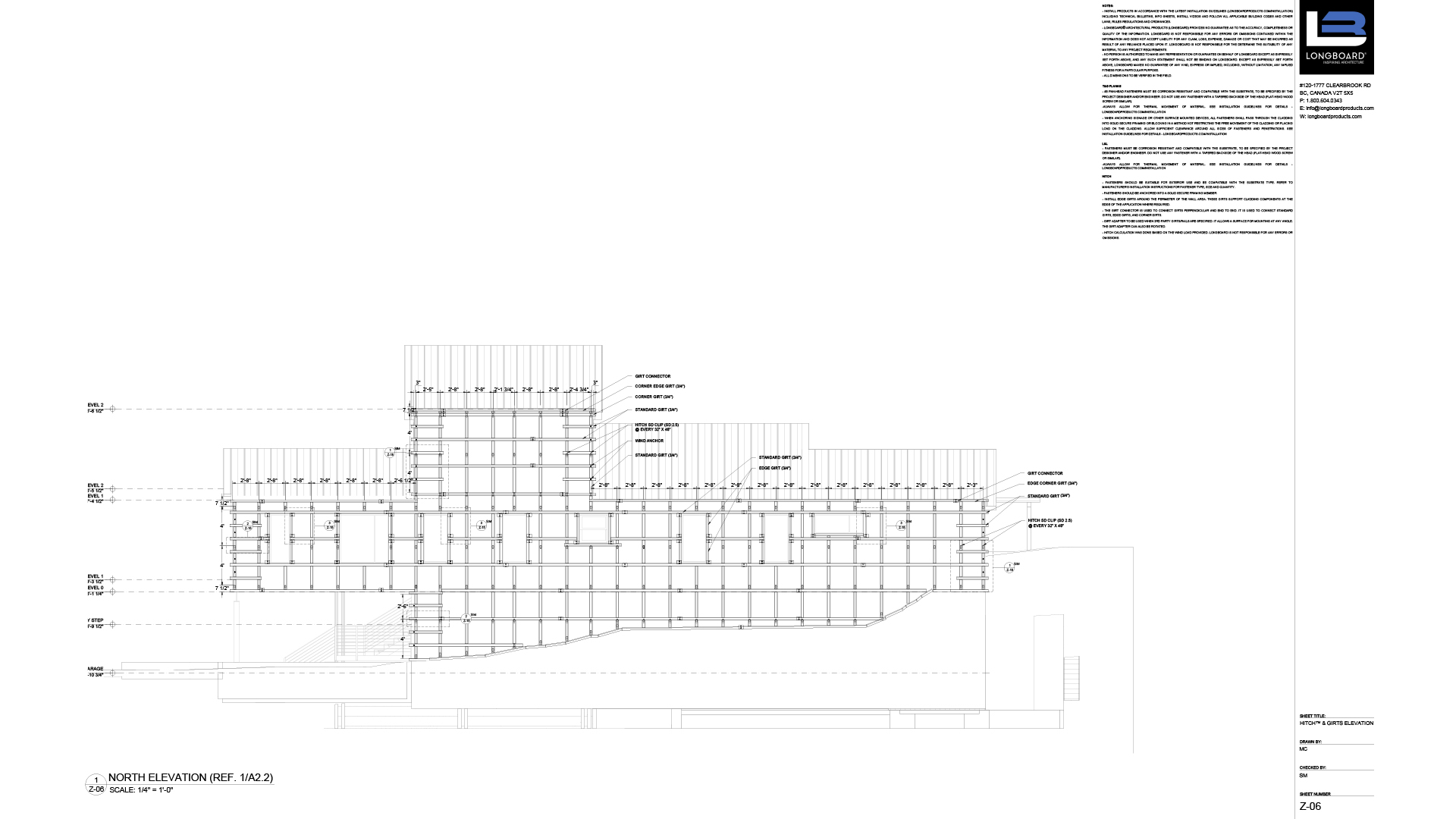

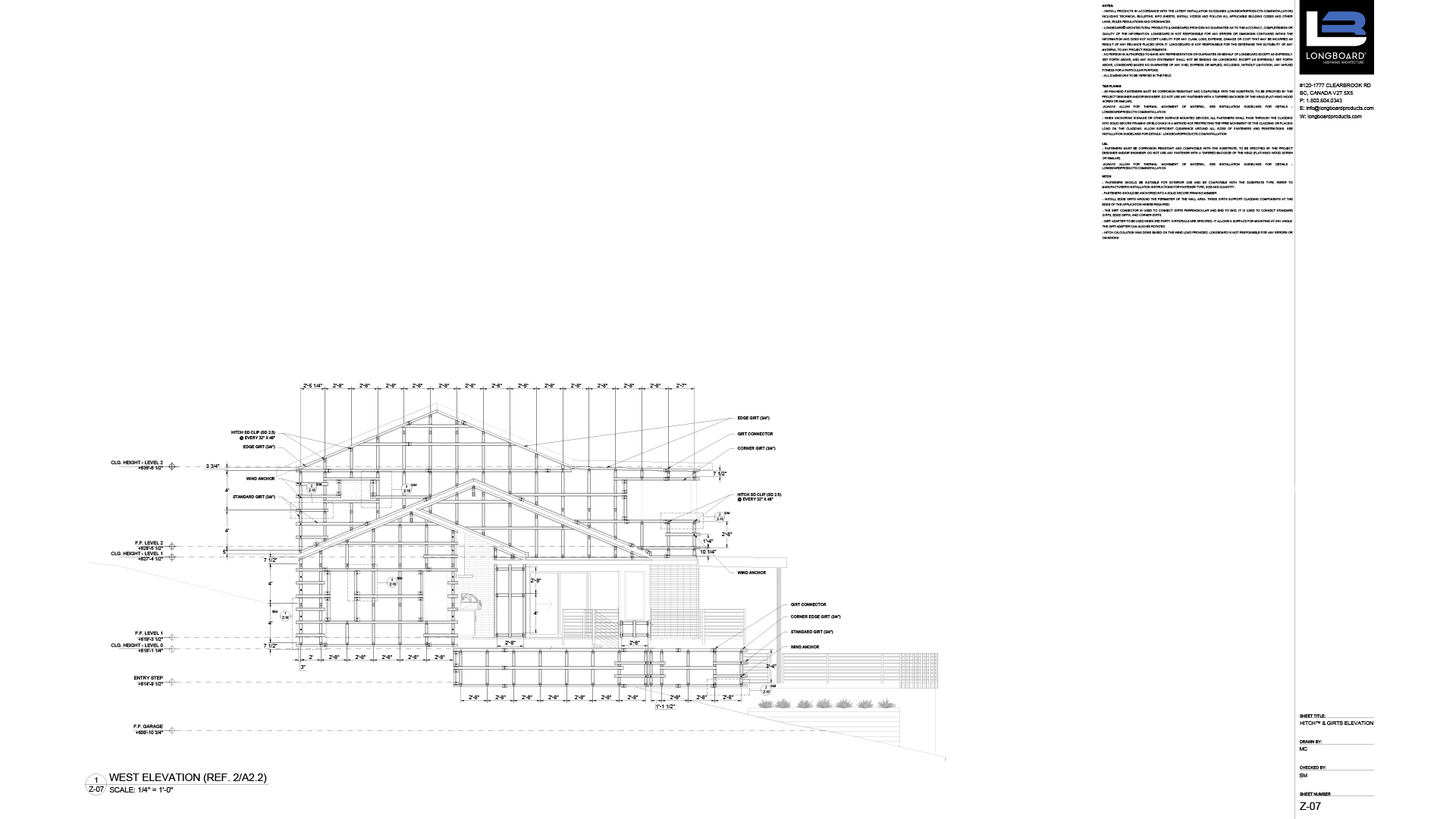

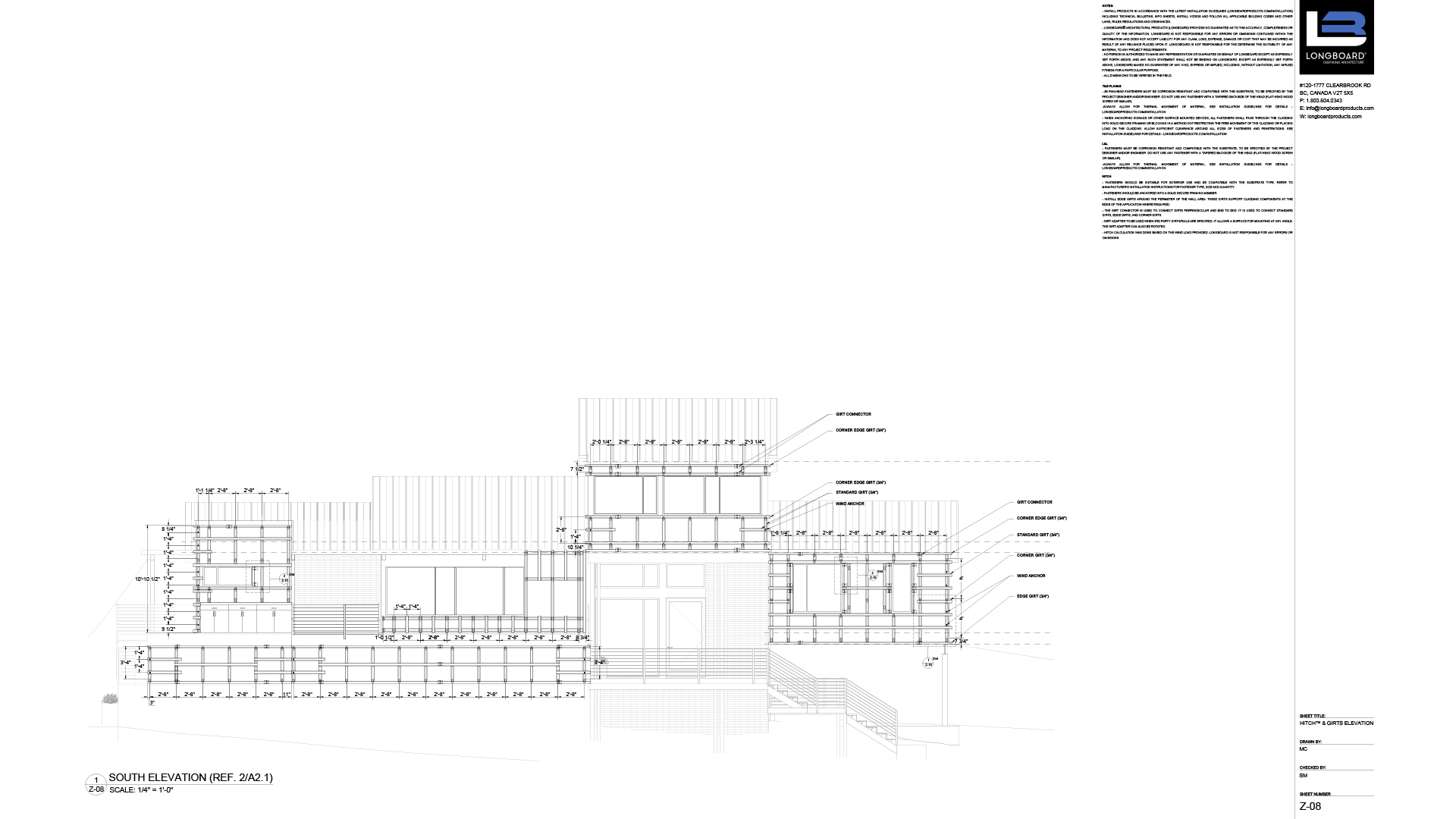

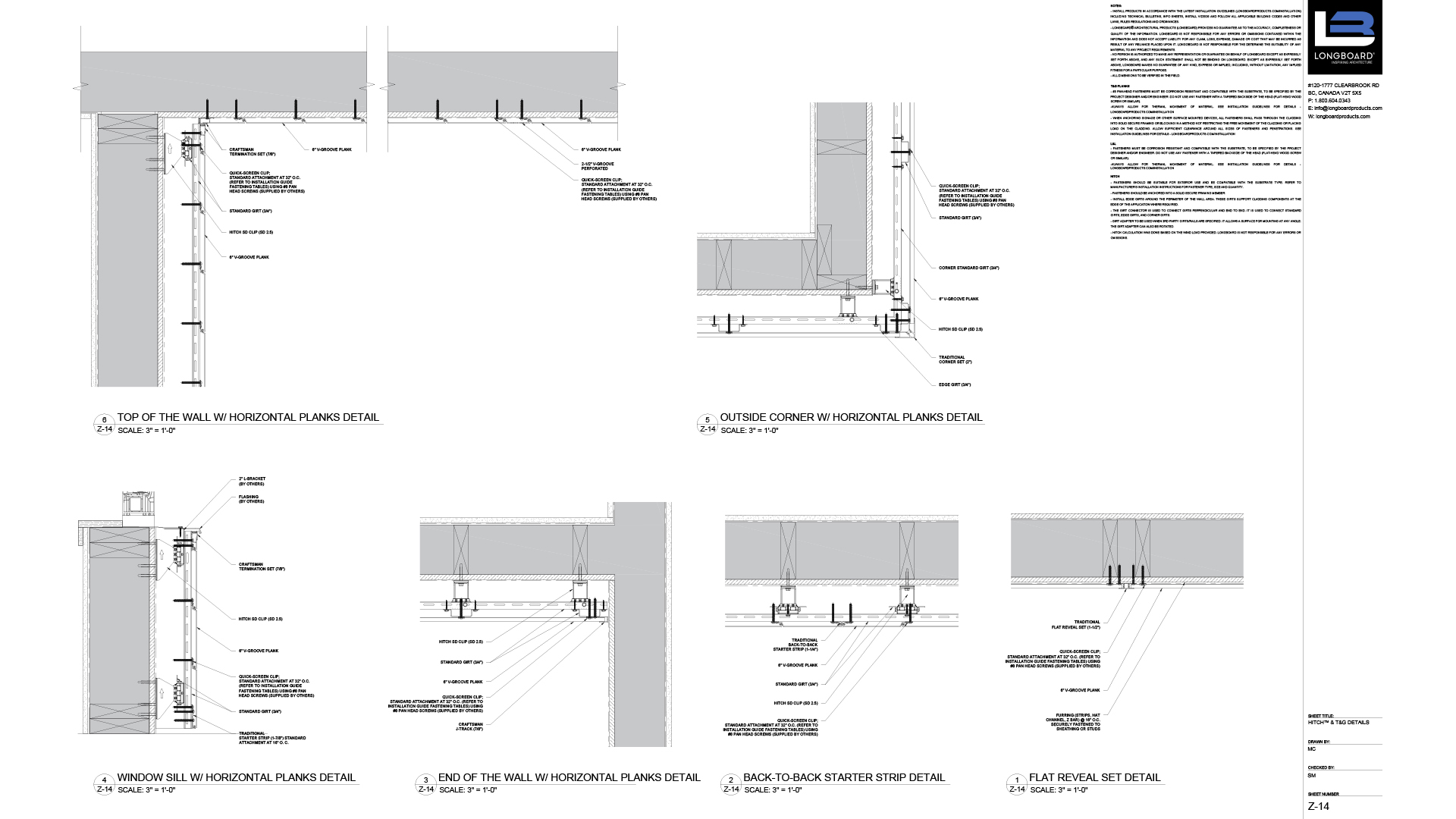

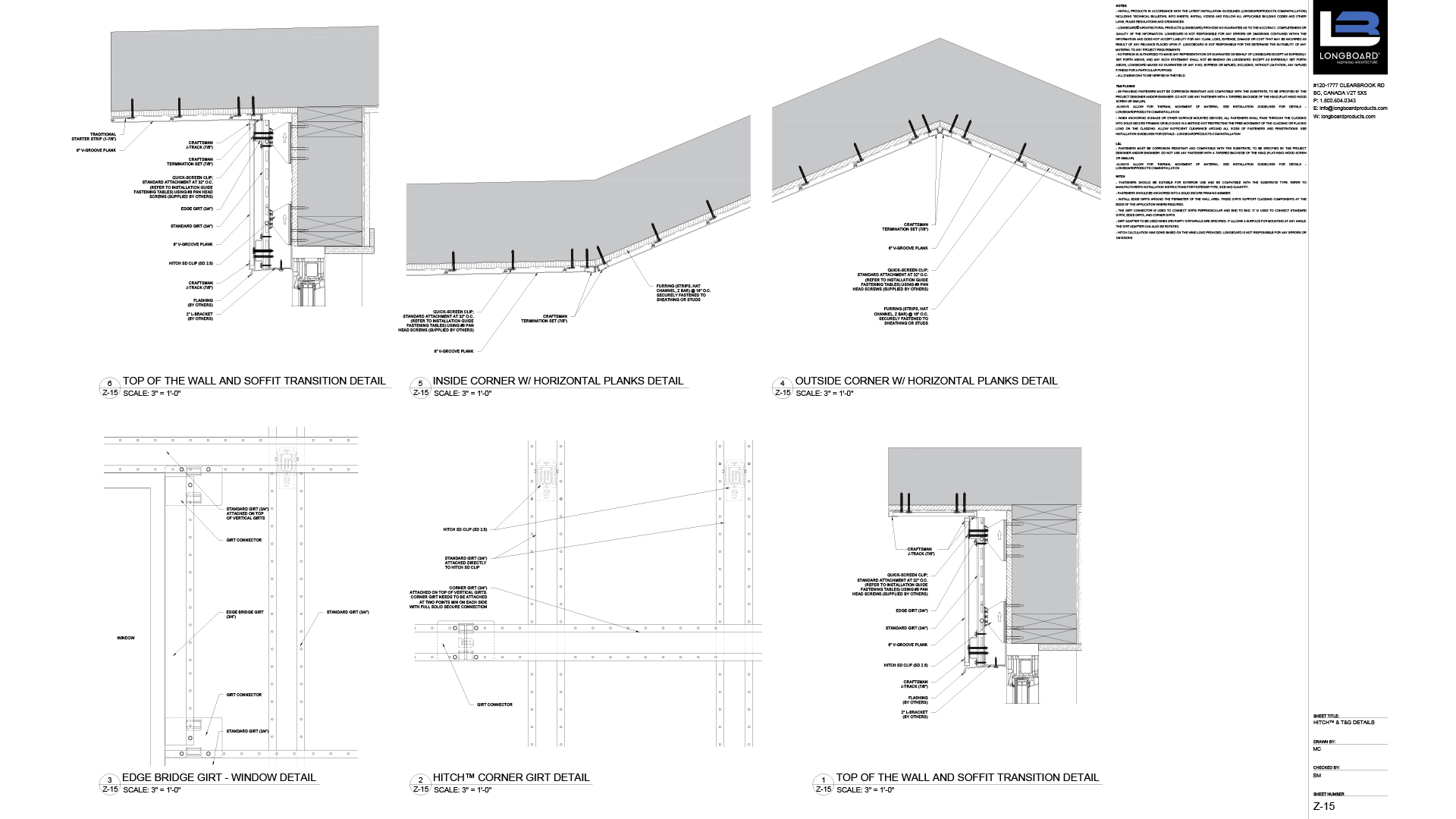

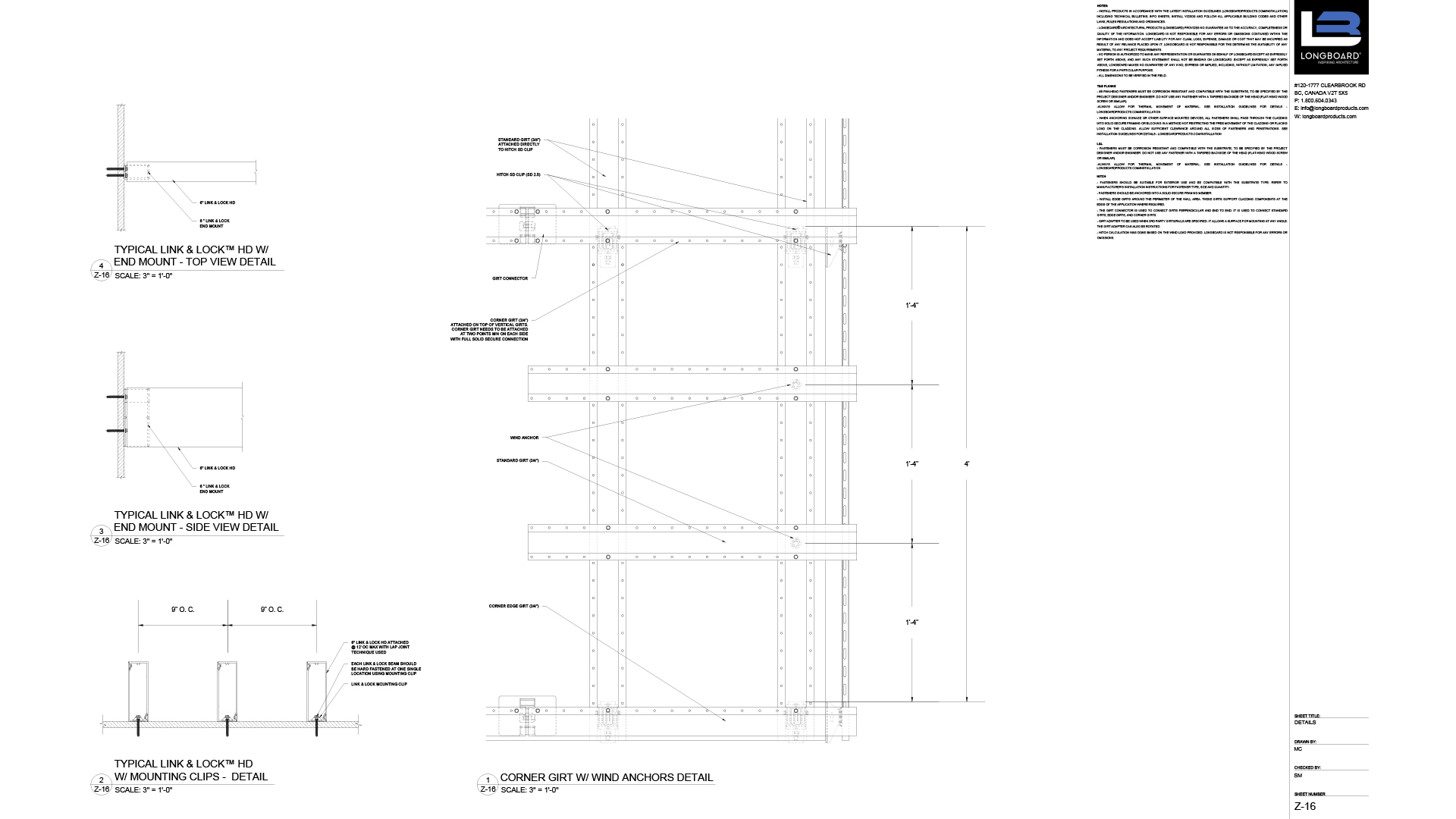

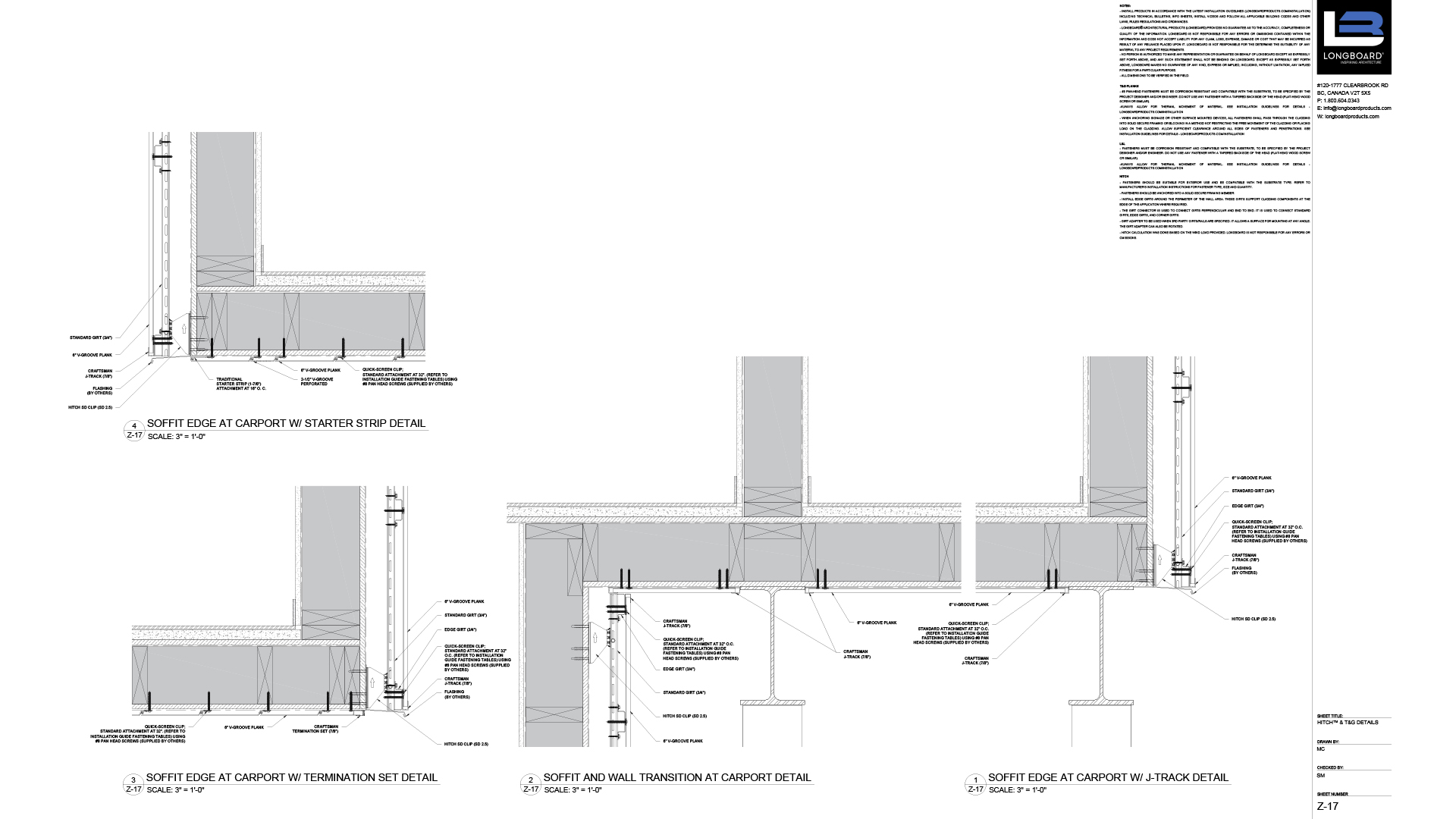

Shop Drawings and Customization

Proper planning and execution were critical to the success of the renovation, and Longboard’s shop drawing services provided essential support. These detailed drawings ensured that every element of the cladding and attachment systems was accounted for, customized to meet the specific wind load requirements and other site conditions. This attention to detail helped ensure that the materials would perform as intended, both aesthetically and functionally. By providing customized plans for installation, the renovation proceeded efficiently despite the complexity of the build. This was particularly important given that the Glauser family continued to live in the home throughout the renovation process, requiring minimal disruption to their daily lives.

Installation Process

The success of Daniel Glauser’s home renovation lay in the precise and strategic use of high-performance materials, all designed to improve the building’s energy efficiency while providing a sleek, modern aesthetic. The installation process began with the ZIP System sheathing, which acted as the foundation for creating an airtight, weather-resistant barrier. This sheathing system was crucial for preventing air leaks and ensuring the home’s exterior remained sealed from the elements. The ZIP System also provided a smooth surface for the subsequent installation of the insulation and attachment systems.

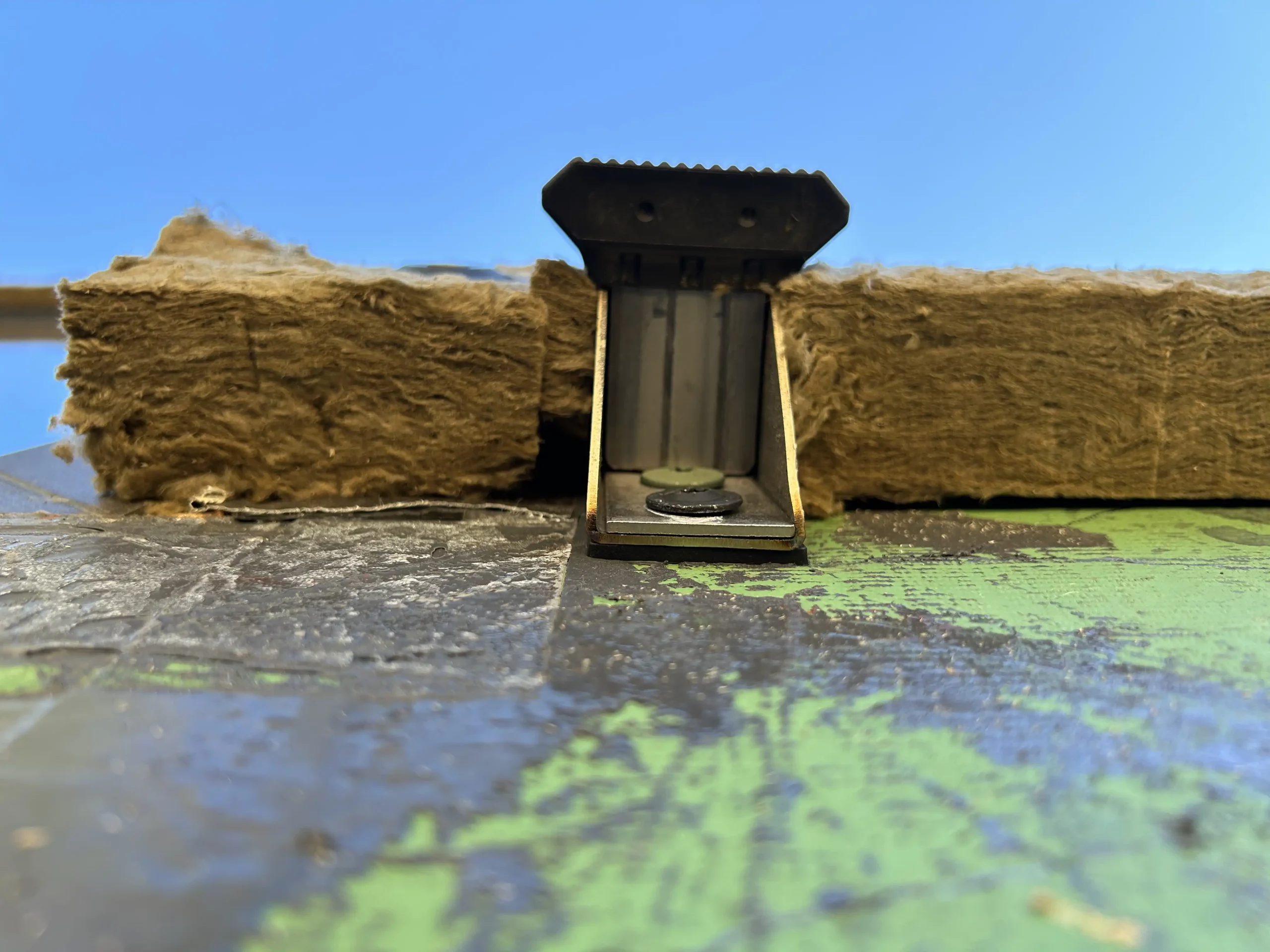

Next, the HITCH™ cladding attachment system was installed, serving a dual purpose of securing the siding and providing critical thermal bridging mitigation. This system, designed with thermally broken components, ensured that the structural integrity of the building was maintained while minimizing heat transfer across the envelope. The HITCH system’s girts provided the necessary structure to attach the exterior cladding.

Following the HITCH system, 2″ Rockwool insulation was added to further enhance the building’s thermal performance. This layer of continuous insulation helped to prevent heat loss during colder months and kept the interior cooler during the summer.

The girt system, integrated as part of the HITCH assembly, allowed for both horizontal and vertical attachment points, facilitating the final step in the process—installing our aluminum cladding. The girts provided a stable framework for the cladding and ensured proper ventilation through the rainscreen design. This layer allowed for air circulation behind the cladding, promoting moisture management and extending the life of the building materials.

Finally, the Longboard 6” V-Groove Planks were installed as the exterior cladding, completing the transformation. These planks, chosen in an Imperial Slate finish, not only provided a modern, sleek appearance but also offered durability and low maintenance. Our aluminum cladding, resistant to weathering and fading, ensures the home’s exterior will retain its appearance and functionality for years to come. The combination of these high-performance materials significantly improved the home’s energy efficiency, while the aesthetic appeal of Longboard’s products gave the house a fresh, contemporary look.

Project Gallery

Closing Thoughts

The final result was nothing short of impressive. Through Daniel’s vision and the execution by his team and partners, a 1970s house was successfully remodeled to look incredibly modern, incorporating long-lasting, sustainable products that also boosted the house’s thermal performance.

Daniel plans to continue monitoring the home’s energy performance, with the potential to pursue full Passive House certification in the future. Achieving this certification would further solidify the home’s standing as a model of sustainable renovation. In addition, he looks forward to tracking the long-term cost savings resulting from the home’s improved energy efficiency, providing further evidence of the benefits of high-performance building practices.

Daniel’s home renovation exemplifies the potential of combining expertise, innovative materials, and sustainable principles to create homes that are not only beautiful and comfortable but also fit for a more energy-conscious future. It stands as a testament to what’s achievable in sustainable home improvement, inspiring others to reimagine their living spaces for enhanced performance and reduced environmental impact.

About Longboard Architectural Products

Longboard Architectural Products is committed to inspiring the design and construction community with innovative architectural solutions that breathe life into their projects. Our diverse range of aluminum products, spanning from cladding systems to architectural screens and beyond, serves both interior and exterior applications.

We prioritize innovation, quality, and sustainability, ensuring that each product is aesthetically pleasing, environmentally responsible, and durable.

Frequently Asked Questions

What specific Passive House principles were prioritized in the retrofit?

The project focused on achieving ultra-low energy consumption through superinsulation, airtightness, and high-performance windows, aligning with Passive House standards.

What were the challenges of living in the home during the retrofit?

The renovation was primarily focused on the exterior of the home. The Sheetrock of the home was kept installed for the majority of the project, allowing Daniel and his family to remain inside the home without much disruption.

What are the long-term maintenance requirements for the materials used?

HITCH™, Link & Lock™ Battens, and 6″ V-Groove Planks are highly durable and require minimal to no long-term maintenance. For the Link & Lock™ Battens and 6″ V-Groove Planks, please refer to our care and maintenance guide for detailed instructions. Cleaning frequency will depend on environmental conditions.

HITCH™ requires no ongoing maintenance; however, it is essential to follow our installation guidelines carefully to ensure optimal performance.