Content Type:

Installation, Performance & Testing

Project Type:

Corporate & Commerical, Education, Hotel/Hospitality

System Name:

T&G Planks

Installation:

Interior, Exterior

Architectural design demands a delicate balance between aesthetic innovation and practical execution. Designers consistently seek methods to create visually distinctive facades and soffits while maintaining installation simplicity and cost-effectiveness. Complex design elements often introduce significant challenges: increased fabrication expenses, extended construction timelines, and heightened technical requirements for installation. The pursuit of architectural differentiation becomes particularly complex when attempting to break the visual monotony of uniform cladding without substantially increasing project complexity or budget.

Architects require solutions that can transform building surfaces through subtle, elegant interventions that do not compromise the fundamental efficiency of construction processes. Butt joints provide architects and designers with an elegant way to break up the visual monotony of uniform cladding without increasing costs or requiring advanced design expertise. By incorporating simple but impactful elements like alternating colors or patterns, butt joints allow for diverse aesthetic expressions while using standard materials. Below are a few examples for inspiration:

Tall City Brewing is a distinctive craft brewery based in Midland, Texas. Established in 2019 by a group of five friends, the brewery draws inspiration from the character and charm of its hometown. The brewery’s welcoming atmosphere is at the heart of its identity, offering visitors a comfortable space to relax, catch up with friends, and savor a selection of unique, in-house-crafted brews.

Bridging the exterior and interior design can be a challenging task, but Tall City Brewing achieved this seamlessly. By incorporating our Table Walnut finish and emphasizing the natural beauty of wood through precise butt joint detailing, the brewery creates a cohesive, warm, and inviting aesthetic that perfectly complements its community-focused spirit.

Next, we explore a remarkable transformation at 1 Wall Street in Burlington, MA. Once characterized by its stark brutalist design, the building underwent a comprehensive modernization project that completely redefined its aesthetic and functionality. The renovation included a full redesign of the entrance-facing façade, new cladding, updated soffits & column cladding, and a total interior makeover.

A standout feature is the striking three-tone pattern across the main entrance area, which effectively breaks up the uniformity of the solid white cladding on the rest of the building. This thoughtful design choice seamlessly integrates the primary colors from the interior design, offering visitors a cohesive and inviting experience from the moment they arrive.

Our final example today is Ray Crow Elementary, the largest of the projects showcased. The alternating pattern on the soffit is not only an eye-catching design choice but also seamlessly connects the exterior and interior. This pattern continues onto the school’s ceiling, creating a unified aesthetic that ties the building’s design together.

In addition to its striking design, the building features a dedicated solar array and a highly sustainable envelope. The envelope incorporates geothermal systems, natural daylighting, solar shading, and enhanced thermal performance. Together, these elements reflect a comprehensive commitment to energy efficiency and environmental stewardship.

Designing with butt joints offers a versatile way to introduce visual interest and texture to a structure without significantly increasing construction costs. Their ability to create clean, modern lines and dynamic patterns makes them an excellent choice for architects looking to innovate with minimal resource investment. However, successful installation requires attention to detail to ensure long-term durability and appearance. Aluminum’s natural expansion and contraction with temperature changes can create gaps between planks in cooler conditions if not installed precisely.

To simplify the installation process, we’ve developed the Butt-Joint Kit—a durable, simple, and discreet solution that ensures a smooth, cohesive appearance while maintaining both functionality and durability. Installed behind the planks, the kit blends seamlessly into the design.

Key Points to Consider:

- Creating Seamless Aesthetics:

- The Butt-Joint Kit effectively fuses two planks into one, enabling a smooth, uninterrupted surface. Multiple butt joints can be connected in a series, with no hard limit on the total length of the installation.

- Thermal Expansion Considerations:

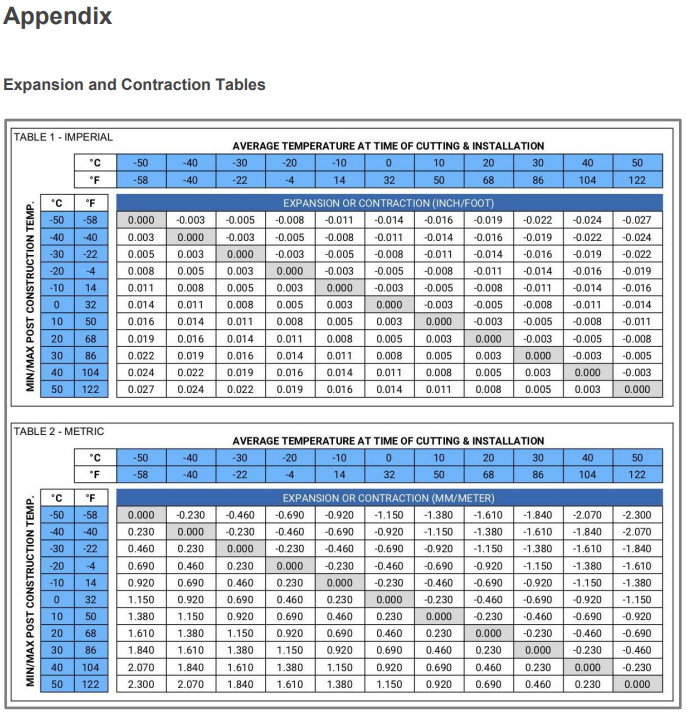

- Aluminum expands and contracts approximately ¼ inch (6mm) over 24 feet (7.3m) within a 54°F (30°C) temperature range. This expansion coefficient remains true no matter how many planks you butt-join together.

- For any installation, it’s essential to account for this movement when choosing your trim components.

Quick Calculation Example:

For a 192-foot aluminum section exposed to a 54°F (30°C) temperature range, thermal expansion and contraction can cause up to 2 inches of total movement. This movement will distribute evenly, resulting in 1 inch at each end of the plank.

To determine the recommended trim width (w) on each side, use the following formula:

w= (Total Thermal Movement/2) x 1.25

Applying this, a 1¼” trim width on each side is recommended.

While the above is an extreme example, the basics around the expansion and contraction remain the same. A similar condition could occur across a shorter run, but much larger temperature range. View our expansion and contraction tables below.

There are a few more important factors to consider as well, such as the required hard fastening a multi-plank run. For complete details and additional guidelines, please refer to our installation guides.