Content Type:

Announcements

Project Type:

Building

System Name:

-

Installation:

Interior

Smart Design for Seismic-Ready Ceilings

Recently, Longboard took on an impressive design assist project that involved creating an entirely new product system from scratch for a highly specific need. The project in question involves the design and implementation of a sophisticated ceiling system to be deployed in seismically active Southern California. The goal is to create a product that is not only functionally robust but also aesthetically pleasing, easy to install, and able to be deployed in areas that are affected by seismic events.

The system is designed to seamlessly integrate with the ceiling, much like established products such as the Dauntless System and Link & Lock™. However, it distinguishes itself through its unique fail-safe design for seismic events, as well as its ability to be removed for access with no or minimal tools required. One of the primary objectives was to create a simple, compact product that incorporates the functionalities of existing systems while ensuring simplicity, ease of use, and minimal material consumption. This compact design is particularly crucial in seismic zones, where regulations demand rigorous adherence to safety and stability standards during seismic events.

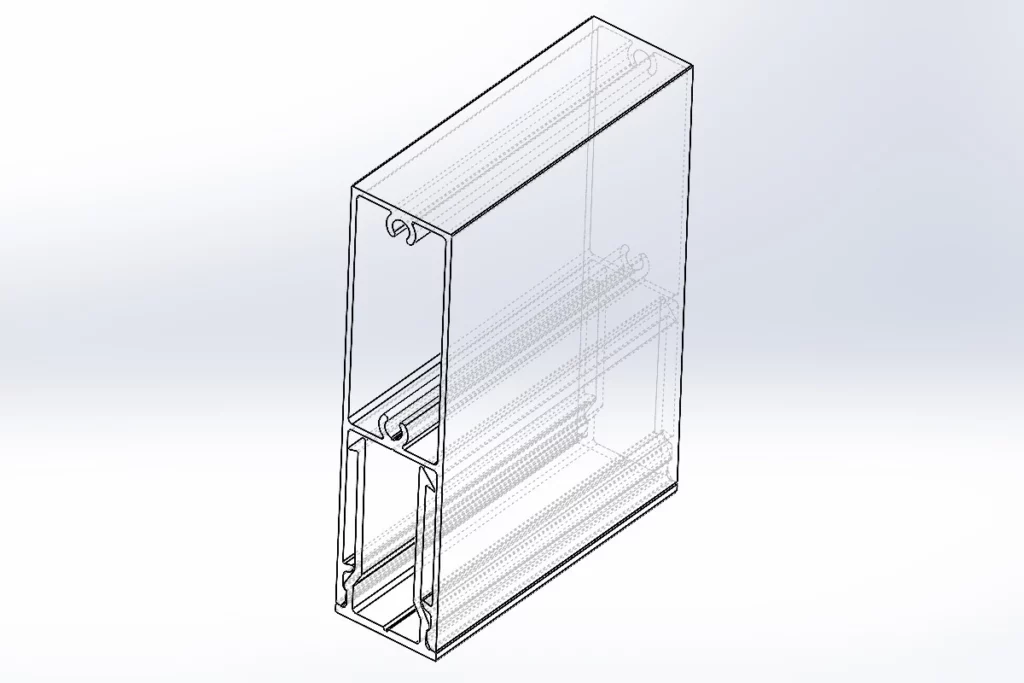

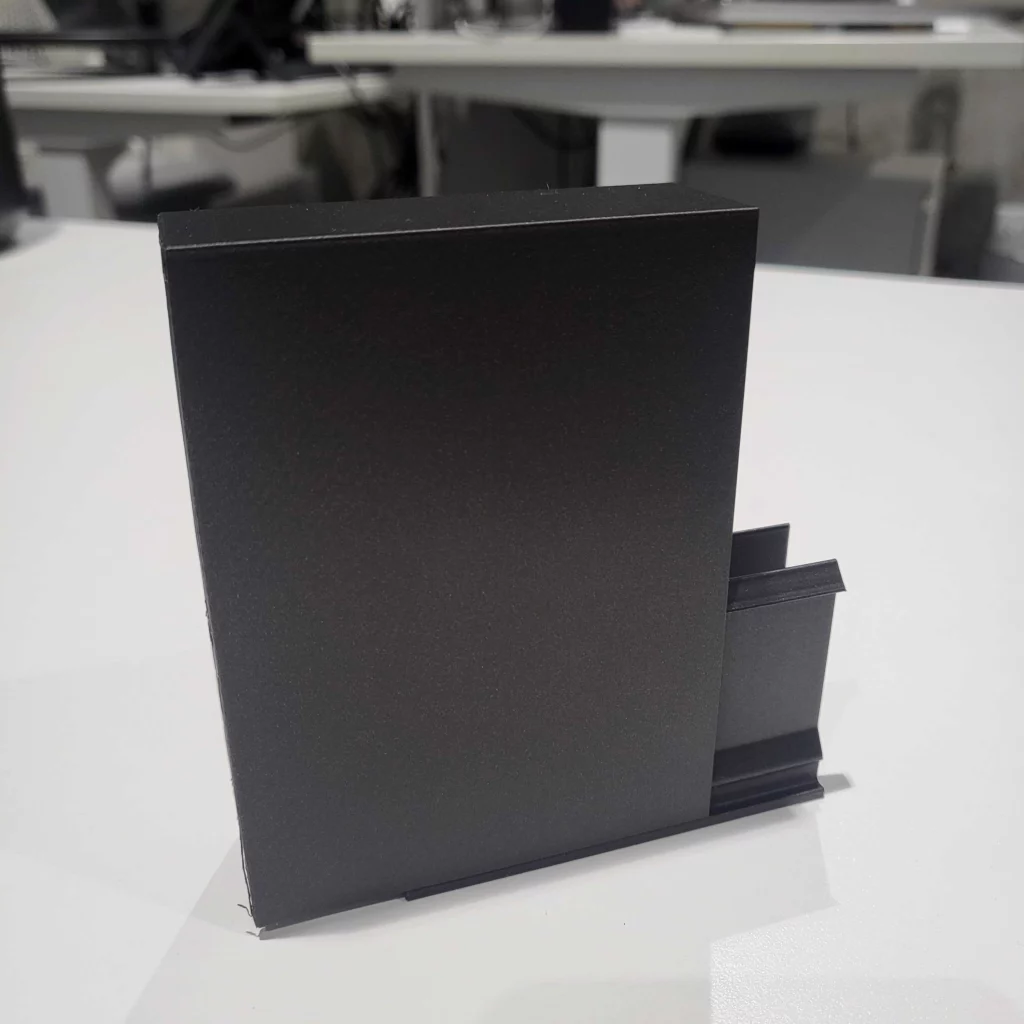

The design process was highly iterative, involving multiple and significant simulations to ensure fixture strength and ease of removal. Advanced CAD software was used extensively to confirm the product’s expected strength, ensuring it could withstand the demands of seismic activity, ease of installation and overall structural integrity. In addition to digital simulations, 3D additive manufacturing was used to create prototypes for hands-on testing and confirmation. Prototypes allow for a tangible assessment of the design’s tactility and user-friendliness, ensuring that downstream users would find the system easy to manipulate and maintain.

The product features dual interlocking aluminum profiles with two distinct engagement stages. The first stage, which is connected to the applied environment, ensures a tight fit to the substrate, which is an obviously crucial initial step. The second stage, the retaining fixture position, allows the attachment to remain suspended without manual intervention or external hardware. A feature that would hold the beam should it become dislodged due to a seismic event or external impact.

Another important consideration for this project was sustainability. The entire system is constructed from aluminum, and material chosen for its recyclability and long-term sustainability. This choice aligns with modern demands for eco-friendly building solutions, ensuring that the product not only meets current functional and regulatory requirements but also supports environmental goals. By using aluminum, the system contributes to a reduced environmental footprint while providing the durability and reliability required.

Our comprehensive approach to design and manufacturing enables us to support a wide range of unique applications. By combining multiple product lines and collaborating closely with clients, we can create fixtures tailored to unique designs. By leveraging our expertise and resources, we can deliver tailored solutions that meet the evolving needs of our clients and the environments in which they operate.

Our product development manager Aaron Fraser talks about working with our clients on these unique projects:

“Working with a client through the journey of a design assist project is a very rewarding experience.

We get to sit in a space where we are working to bring the client’s vision to life and add value to their project. At the same time our design team works tirelessly to create simple, easy to understand solutions that elevate the overall full project experience.

We thrive on the challenge of creating exceptional products with a focus on sustainability, value, ease of installation, and lasting durability.”

This project exemplifies our dedication to innovation, sustainability, and client satisfaction. By working to build a product designed to be safe and functional in seismic applications, we have developed an attachment system that meets the highest standards of performance and sustainability. Our approach ensures that our clients receive a product that is both reliable and adaptable to their unique needs, reinforcing our position as a leader in the industry.