Content Type:

Trends

Project Type:

-

System Name:

Hitch™

Installation:

-

As the building and construction industry accounts for approximately 40% of global carbon emissions, now more than ever, it’s important to be thinking about how we’re manufacturing for the longevity of the products and for future generations. Aluminum stands out as one of the best options for sustainable building materials, for many reasons. Along with other innovative products, companies, and technologies, we are headed in the right direction for this industry.

Why Aluminum?

One of the most sustainable materials in the manufacturing and product development space is aluminum. An infinitely recyclable material that can support a circular economy as it doesn’t degrade or lose its physical properties, and can continue to be produced into the same quality product.

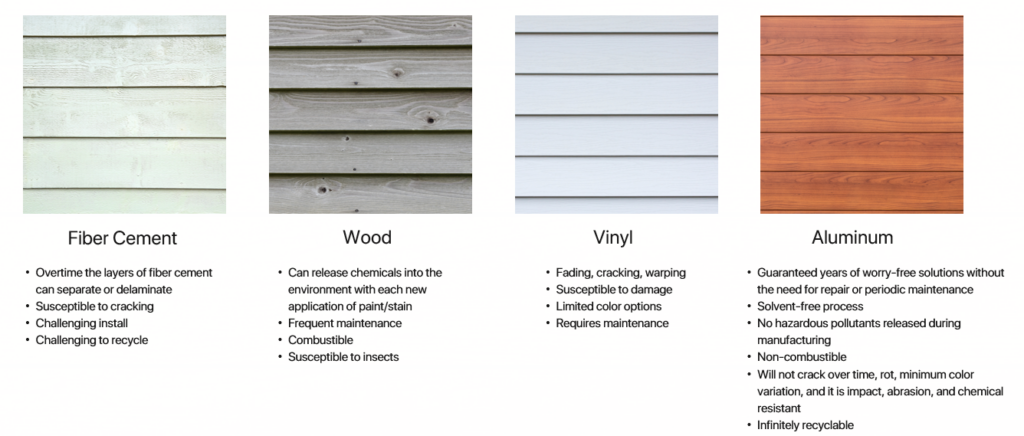

Aluminum is abundant, lightweight, non-combustible, durable, corrosion-resistant, health-safe, and versatile. It allows it to be used in a variety of applications across multiple industries – construction, architecture, transportation, electrical appliances, and consumer goods, to name a few. It’s important to recognize why aluminum would be used over other materials in the building industry.

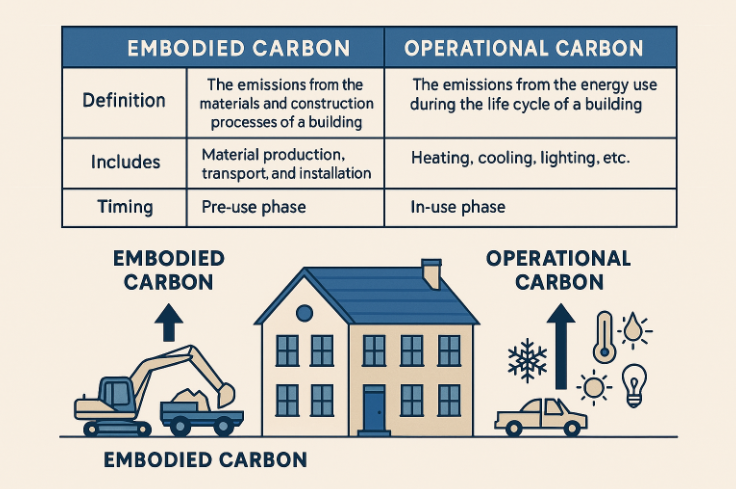

Longboard ECO™

Beyond breakthroughs on the production side of aluminum, Longboard ECO™ is moving the needle on sustainable products with a collection of products that contain recycled aluminum. This allows for less greenhouse gas emissions and generates less than 50% of the industry average embodied carbon. The Longboard ECO™ products we produce follow a strict standard of quality control.

Longboard Architectural Products promises to ensure their Environmental Management Systems (EMS) deliver according to existing local and international standards. Always looking to improve their environmental performance by regularly reviewing policies and their impact on the environment.

ELYSIS® – A New Era for the Aluminum Industry

The greatest breakthrough in the aluminum industry since it began in 1886 is ELYSIS®. Announced in 2018, and aiming to launch technology available for installation this year. This partnership between Rio Tinto, Alcoa, Apple, and the Canadian and Quebec Government has created the world’s first carbon-free aluminum smelting process.

It features the newly developed breakthrough proprietary materials that are stable and do not react during the process. It eliminates all direct greenhouse gas (GHG) emissions from the aluminum smelting process and is the first technology ever that emits oxygen as its by-product.

This is a huge step for the aluminum industry and a step in the right direction in making our world a more sustainable and cleaner place. The benefits of ELYSIS® are abundant, but here are some of the highlights:

- Eliminates GHG emissions and seven other by-products of aluminum production

- Reduces the carbon footprint for transportation, construction, electrical, and consumer goods

- Increases process efficiency through proprietary electrode materials, enabling higher productivity

- Extends anode lifespan, lasting several years compared to traditional 25-day replacements

- Improves productivity with a unique vertical anode/cathode geometry for the same surface area

HITCH™

Further to Longboard’s ECO™ line is a product to aid in the reduction of operational carbon emissions when possible. With their innovative, patented modular solution, cladding attachment system, HITCH™. The most efficient methods of insulating a building’s exterior walls are those that incorporate the principles of continuous exterior insulation with little to no thermal bridging to limit thermal loss. The HITCH™ is sustainable and is working to lower operational carbon; here’s how:

- Recognized by Passive House Institute as an Advanced Component Facade Anchor for cool and temperate climates

- Delivers up to 94% thermal efficiency, reducing heat transfer and boosting energy performance

- Supports for 1”-16” continuous exterior insulation to meet aggressive energy targets and code requirements

- Resistance to extreme conditions for long-term durability

- Modular design with built-in flexibility for diverse applications

- Construction with premium, non-combustible materials, ensuring a 50+ year service life backed by proven performance

We are seeing a more sustainable future take shape product innovations and advancements in production technology. These breakthroughs make it possible to cut carbon emissions by up to 50%, reduce operational carbon, and produce aluminum with technology that’s able to generate oxygen instead of carbon dioxide. This is just the beginning of what we can achieve in building a more sustainable world.